CNC wire and flat stock bending machines

Bend wire and flat stock with precision and speed using our industrial CNC bending machines

Our 3D CNC Wire Bending Machines

Our 3d cnc wire bending machine range combines precision, speed, and versatility for modern production needs on a wide range of industrial application such as automotive, aeronautical, furniture, constryction, HVAC… Partticulary well-suited for small and medium production runs, each machine can process wire from coils or cut-to-length bars with minimal tooling costs and quick setup. The touchscreen interface and three-dimensional graphic programming make part setup and the repetition of complex parts easy. Each macine ensures ensures accurate metal wire bending reardless of diameter or material and can easily be integrated into your production lines.

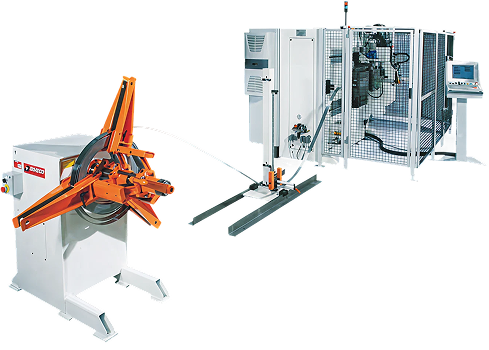

Robomac e-Motion

From Ø.08″ to Ø.375″

(Ø2 to Ø12 mm)

100% electric bending machine, fast, precise and versatile. Ideal for optimized cycles.

Learn more

Robomac TF

From Ø.08″ to Ø.625″

(Ø2 to Ø16 mm)

Robust, high-performance machine, world-renowned for years of proven reliability.

Learn more

Robomac TFE

From Ø.08″ to Ø.625″

(Ø4 to Ø16 mm)

100% electric, with high precision and short cycle times

Learn more

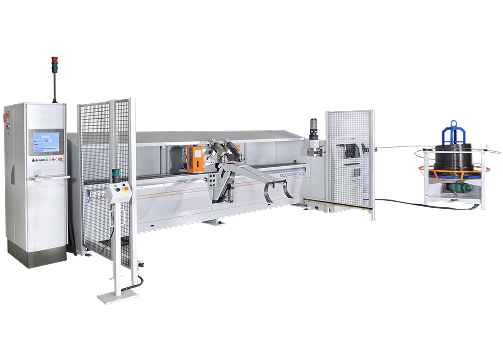

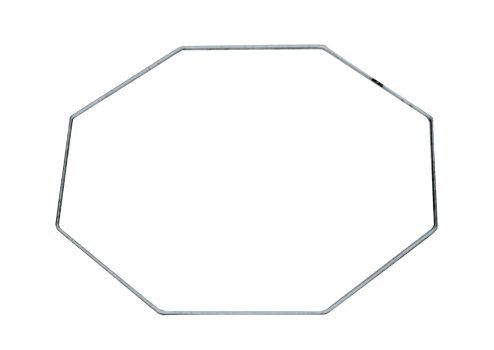

Robomac 2 heads

From Ø.065″ to Ø.47″

(Ø1.8 to Ø12 mm)

Double head for long lengths, with close bending thanks to a retractable central head.

Learn more

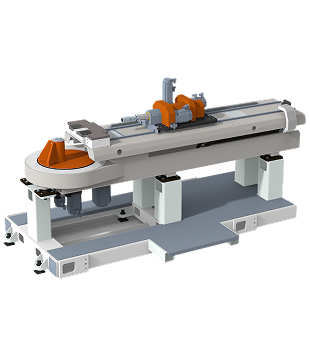

Robomac 4 heads

From Ø.07″ to Ø.16″

(Ø1.8 to Ø4 mm)

Exceptional cycle times thanks to 2 parallel benches and 4 simultaneous folds.

Learn more

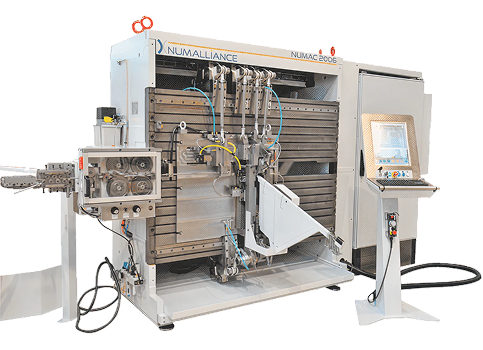

Numabend T815

From Ø.16″ to Ø.51″

(Ø4 to Ø13 mm)

Compact and easy to integrate into agile cells, for forming wire and tube from coils or bars.

Learn more

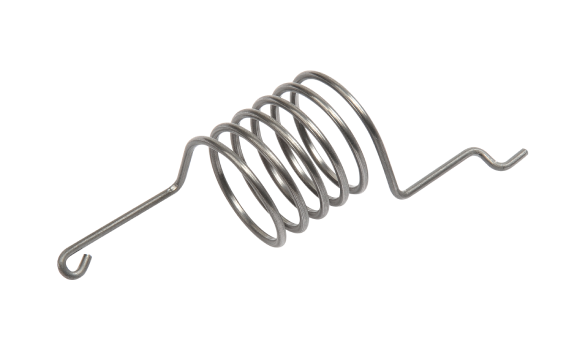

FRX

From Ø.03″ to Ø.25″

(Ø0.8 to Ø6 mm)

Compact, flexible machine, ideal for spring coiling.

Learn more

F46 / F47S

From Ø.04″ to Ø.28″

(Ø2 to Ø7 mm)

100% electric, fast and precise, for small or highly developed parts.

Learn more

F37SP

From Ø.08″ to Ø.16″

(Ø2 to Ø4 mm)

3 digital axes, cut after bend: ideal for short lengths and excellent repeatability.

Learn more

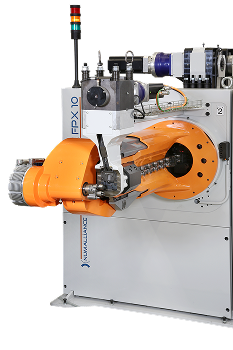

FPX Busbar

From .35×.12″ to .98×.31″

(9×3 to 25×8 mm)

The precision solution for your busbar production

Learn more

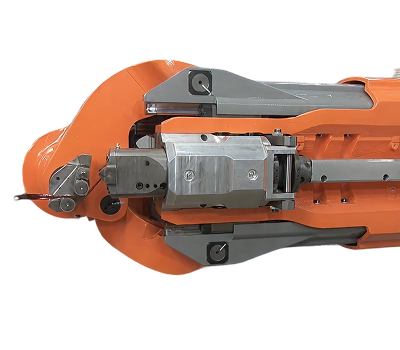

FPX

From .35×.12″ to .47×.16″

(9×3 to 12×4 mm)

The precision solution for flat bending with secondary operations

Learn more

FTX

From Ø.12″ to Ø.625″

(Ø3 to Ø16 mm)

Thanks to an arm that can move around the wire, the FTX allows for slip-free bending and double bending.

Learn more

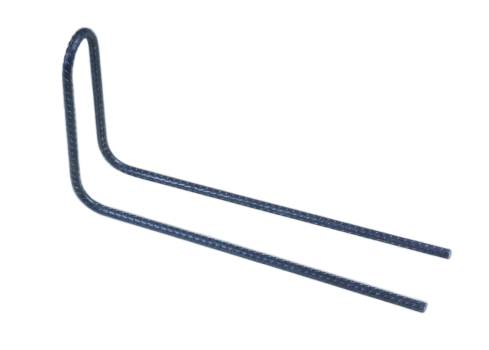

Our 2D CNC Wire Bending Machines

Our 2D CNC wire bending solutions for 2D applications are ideal for manufacturing long, symmetrical, or complex parts requiring tight bends. Easy to program and adjust, each cnc wire bender guarantees exceptional repeatability and smooth, reliable production, even for the most demanding geometries.

These machines ensure faster and greater precision in wire bending for large, high-volume production runs. The integrated technologies reduce manual adjustments and simplify the handling of multiple parts, simplifying the transition to mass production.

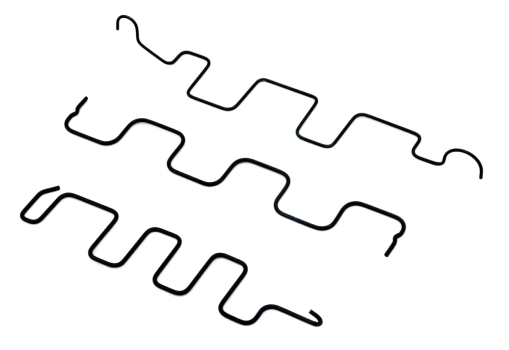

Discover Our CNC Multi-Slides wire Bending Machines

Developed from traditional mechanical systems, our wire bending models with multi-slide technology offer high-speed, repeatability, and durability for high-volume production. Every machine allows quick tool changeover, maintains a clean production environment, and can be fully customized to match your requirements.

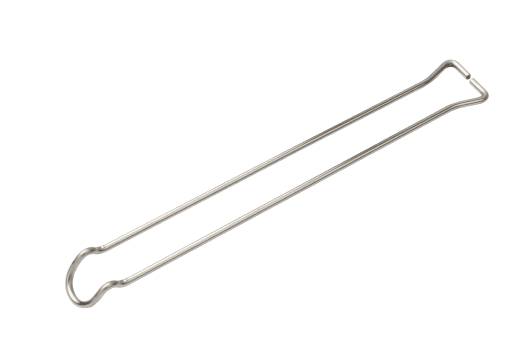

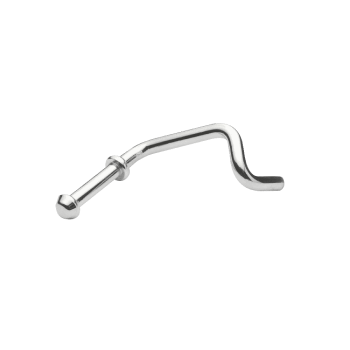

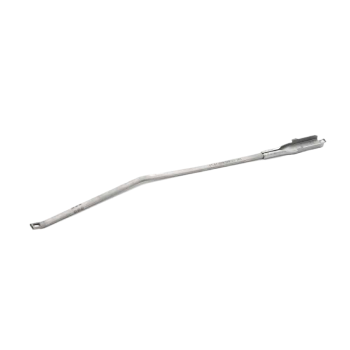

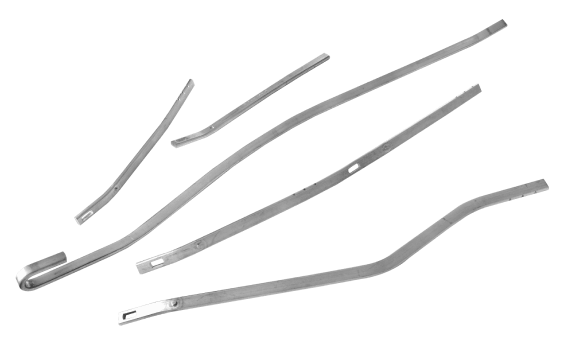

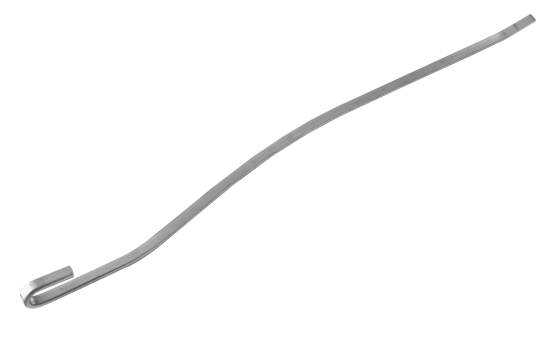

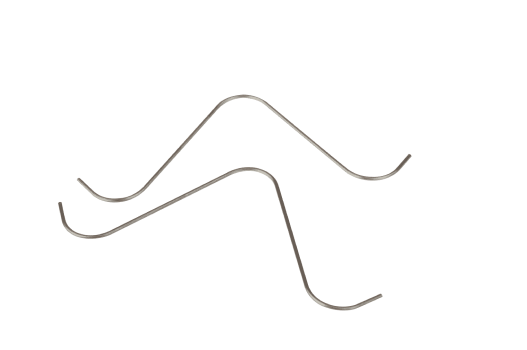

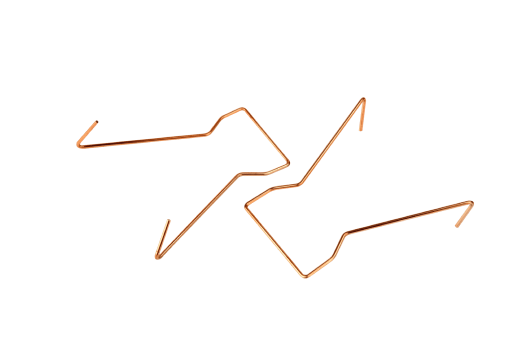

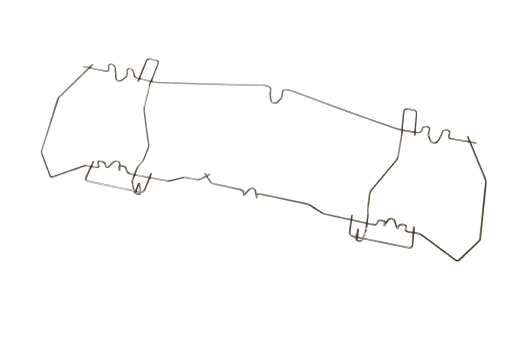

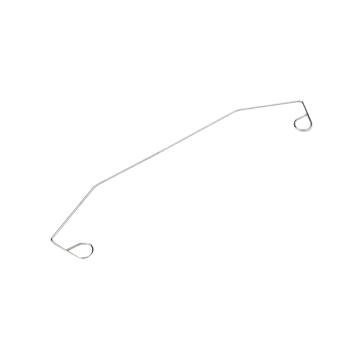

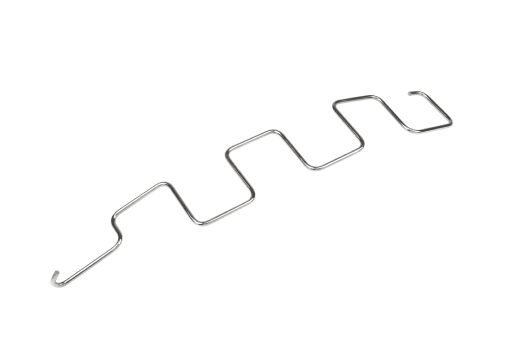

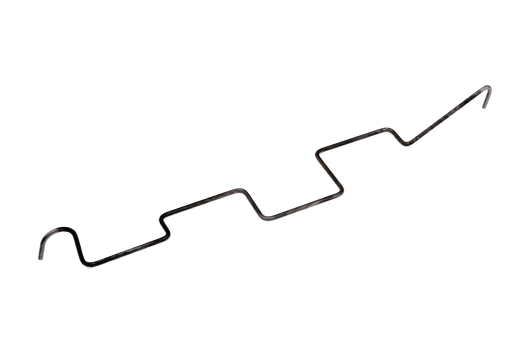

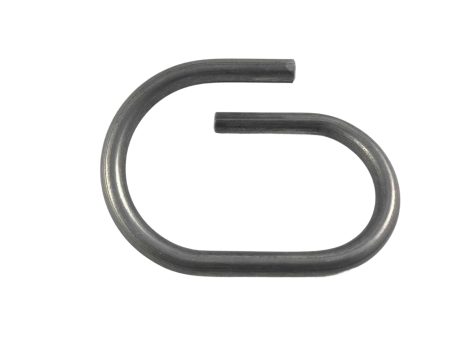

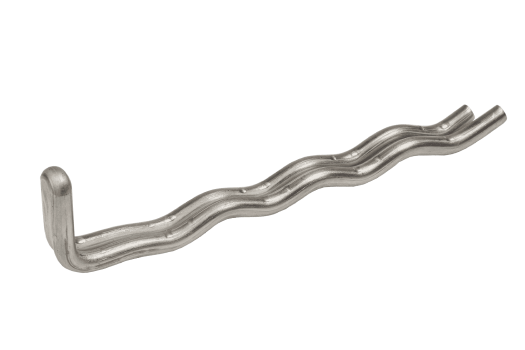

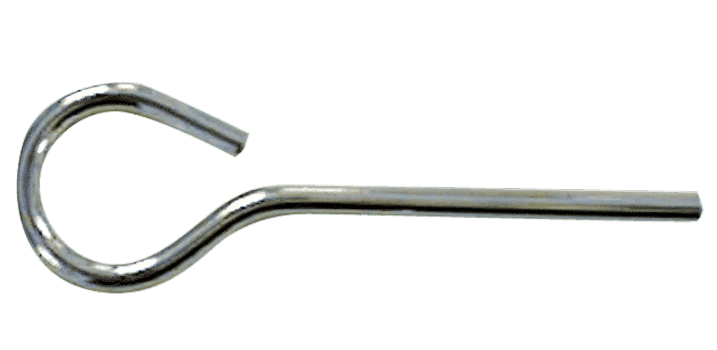

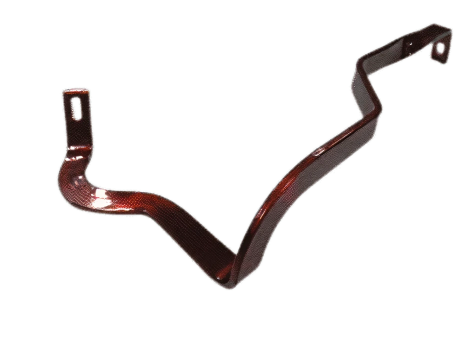

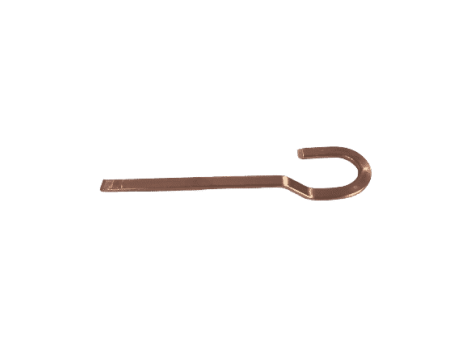

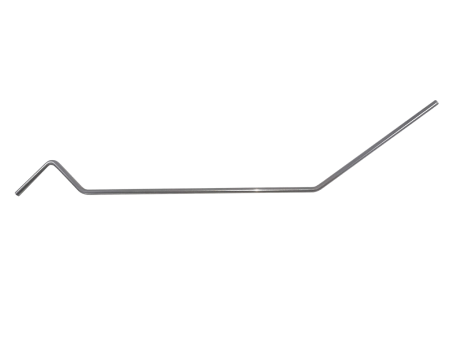

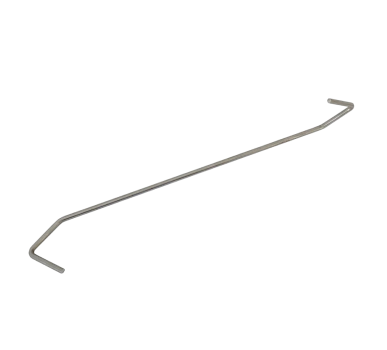

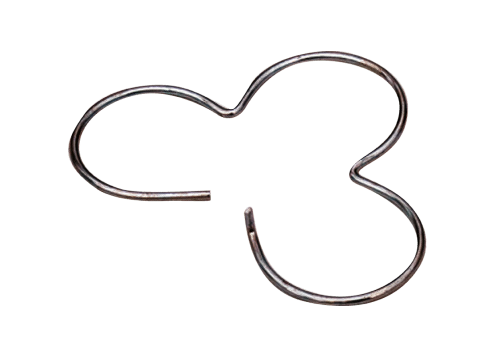

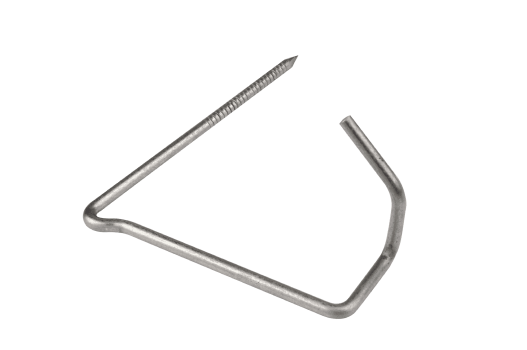

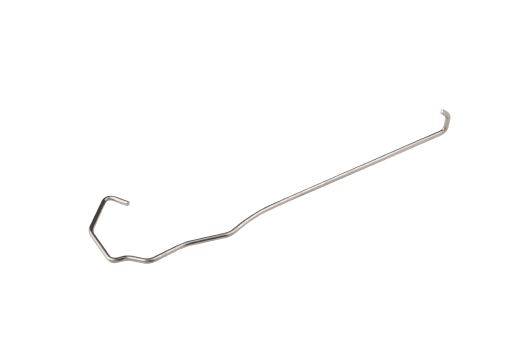

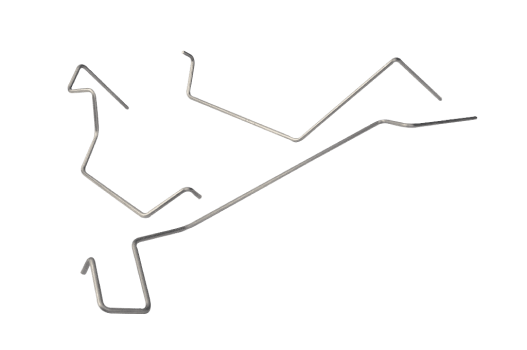

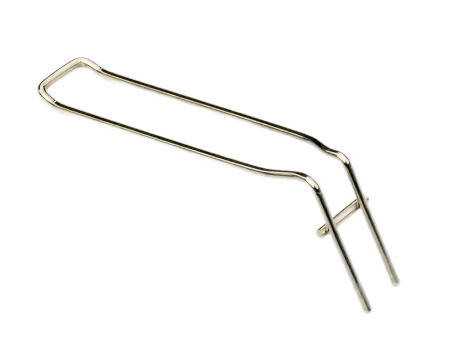

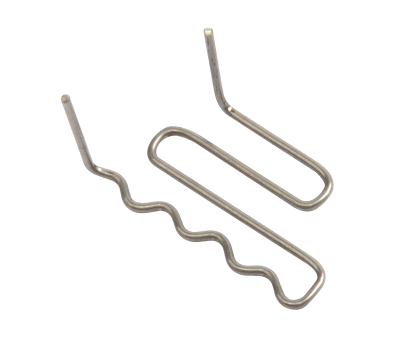

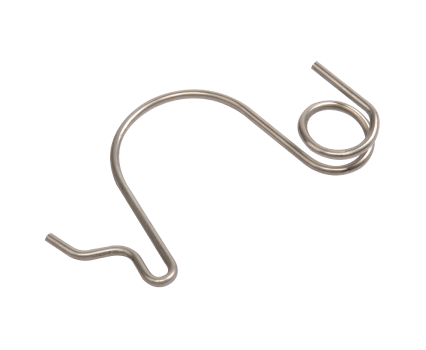

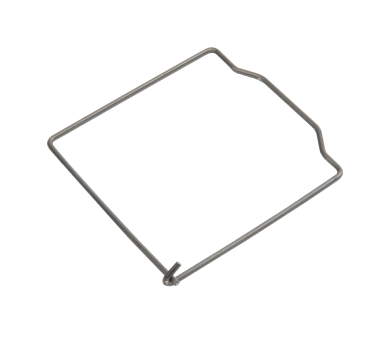

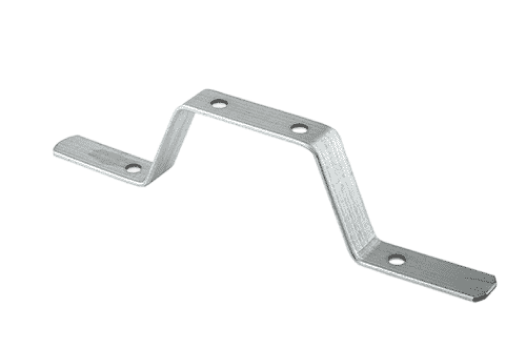

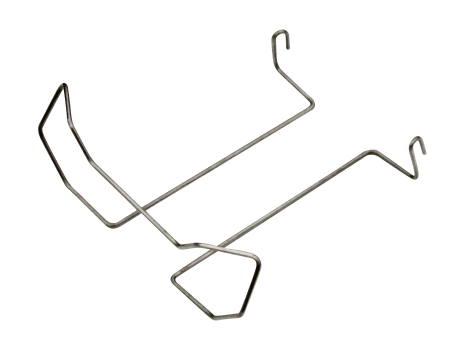

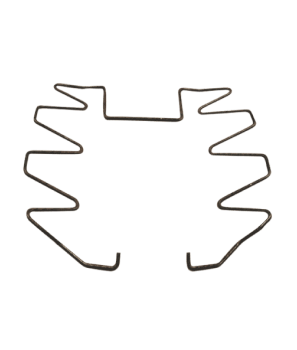

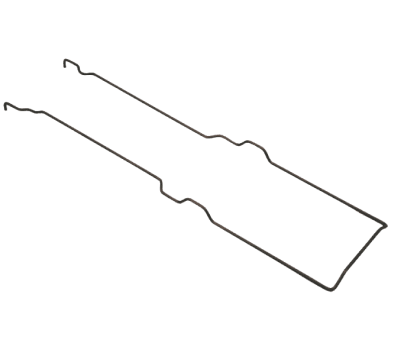

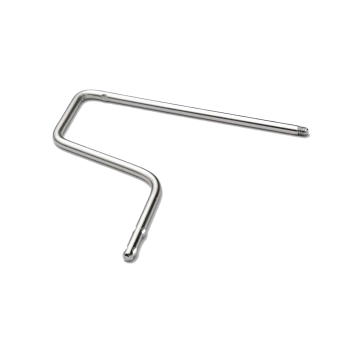

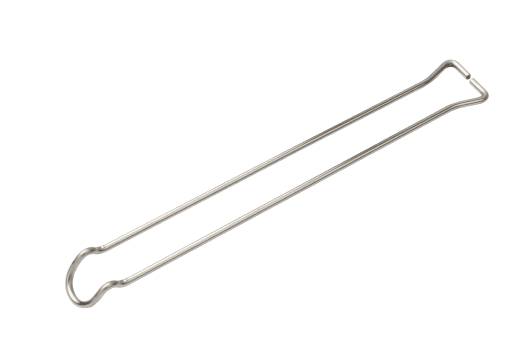

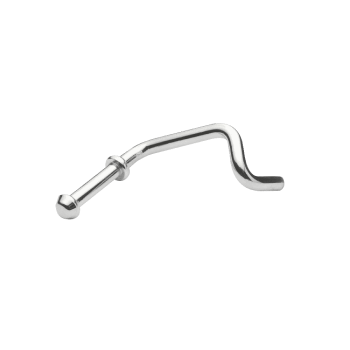

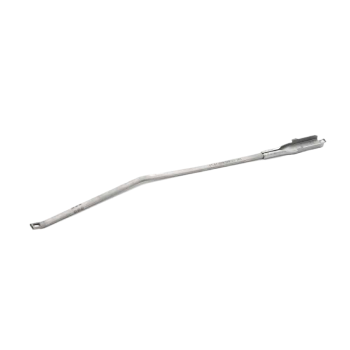

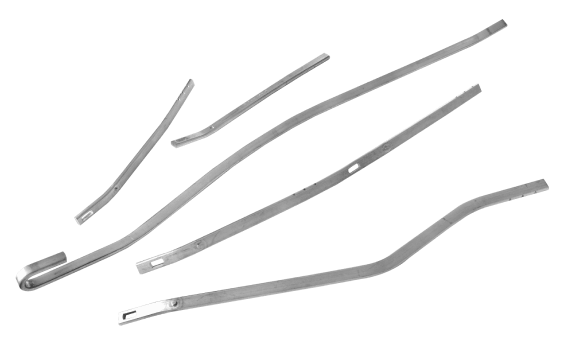

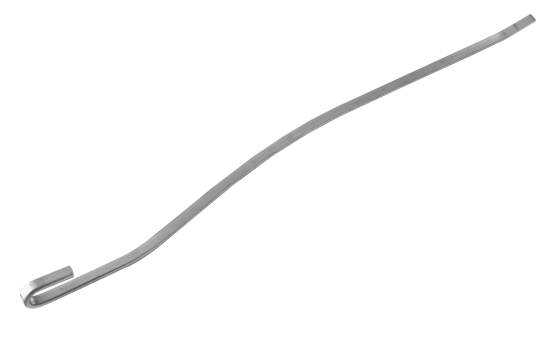

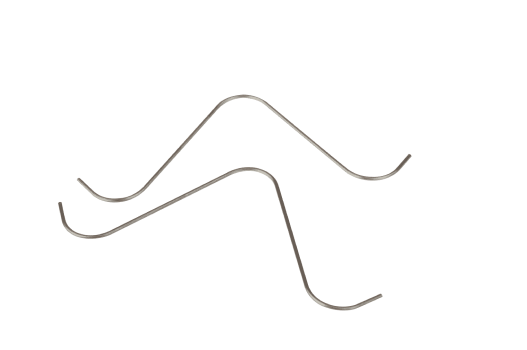

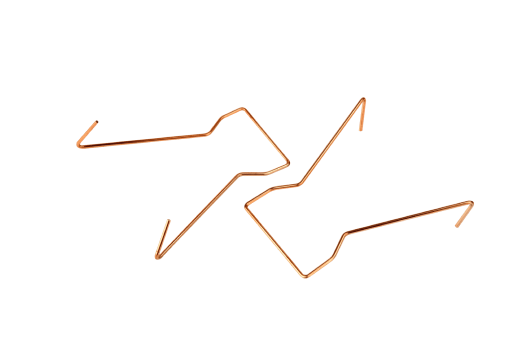

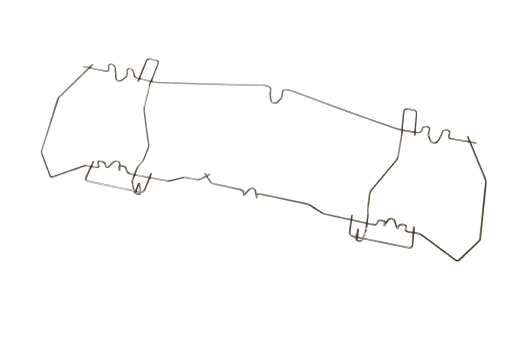

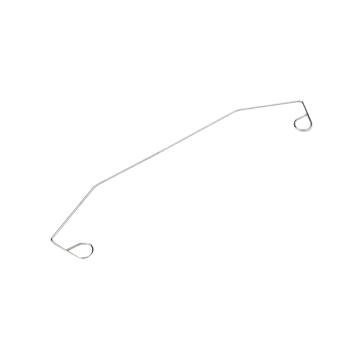

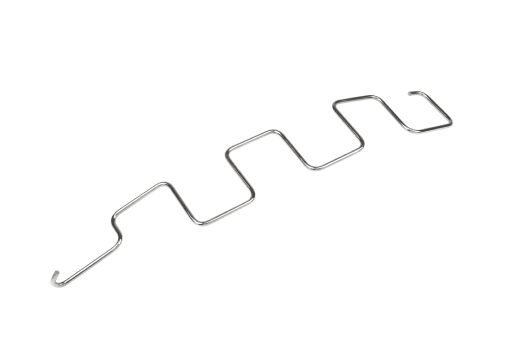

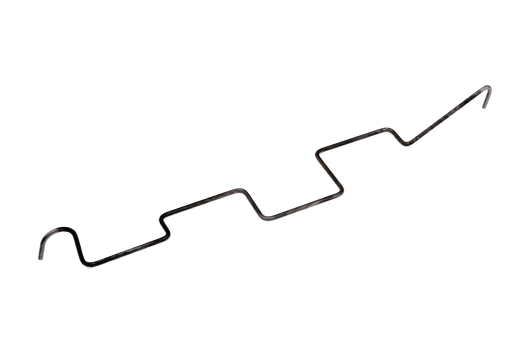

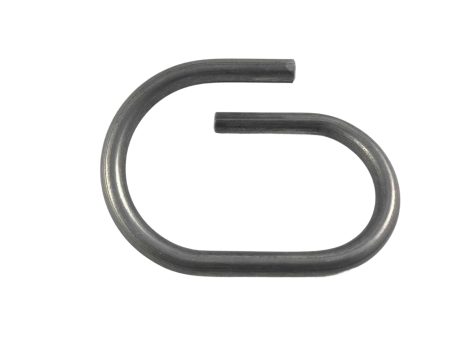

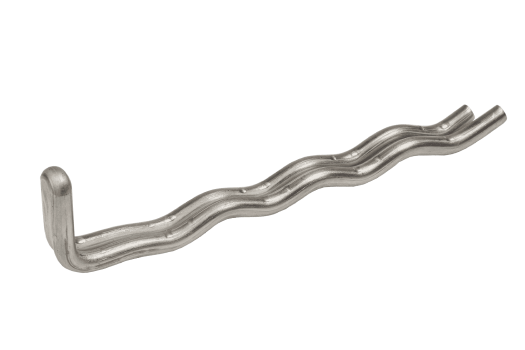

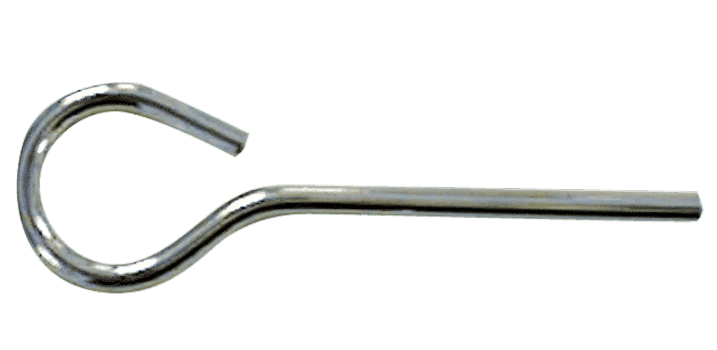

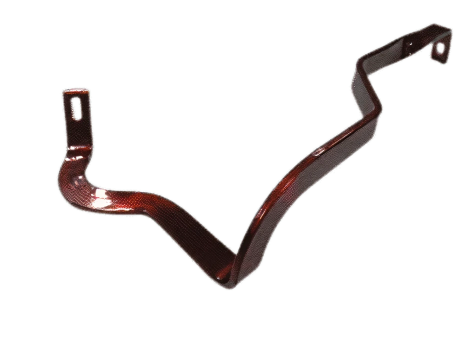

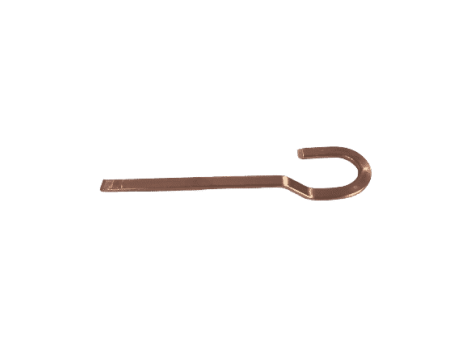

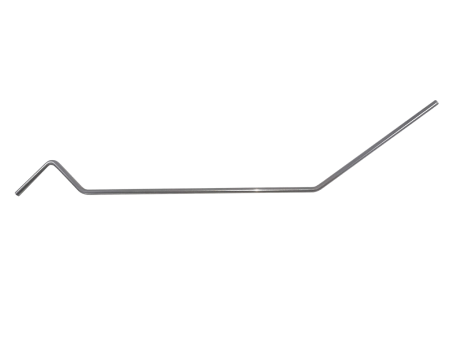

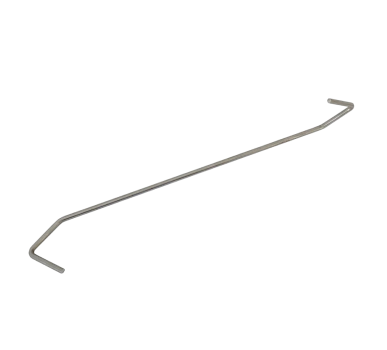

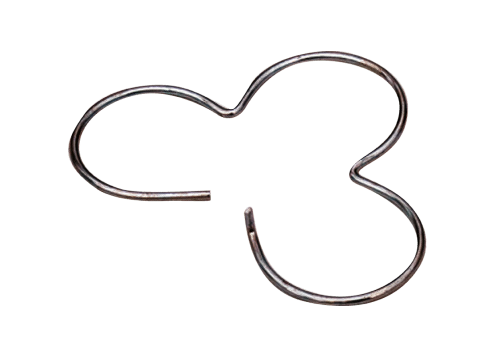

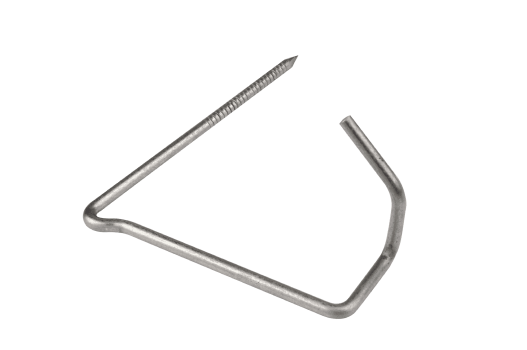

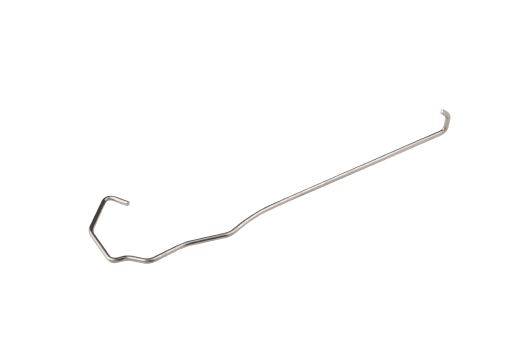

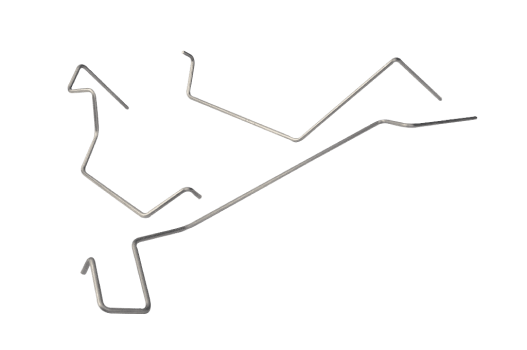

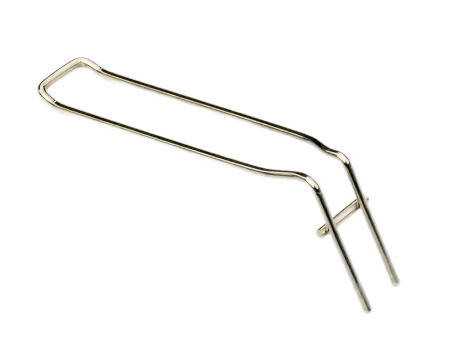

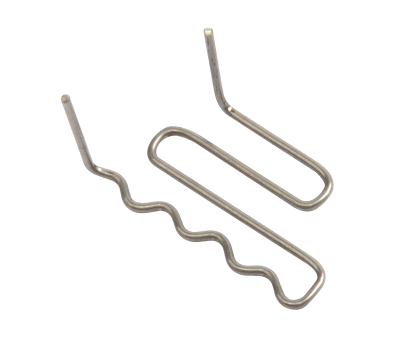

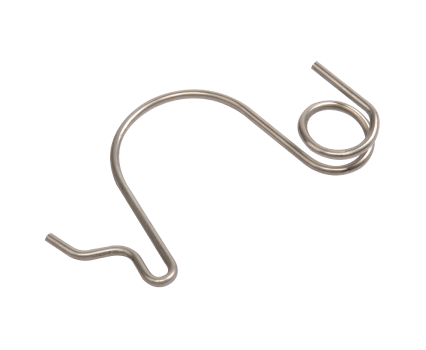

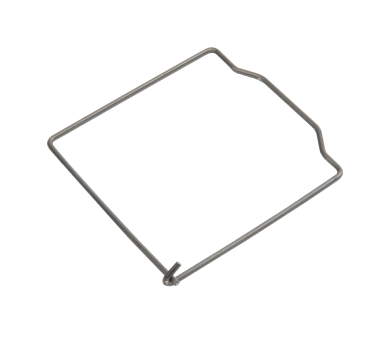

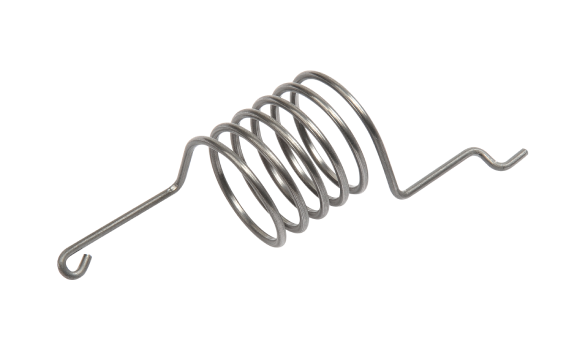

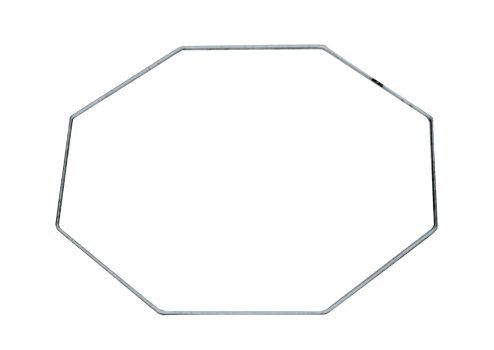

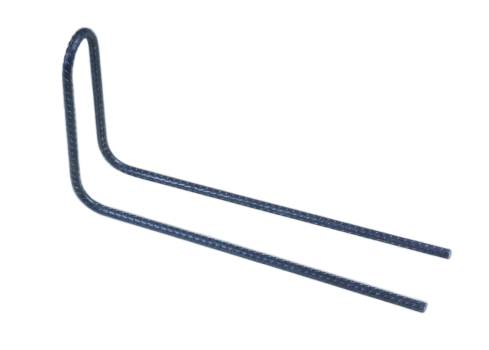

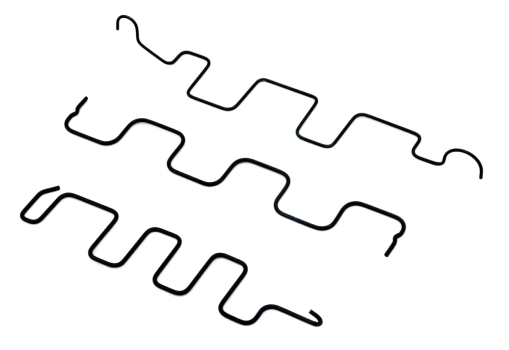

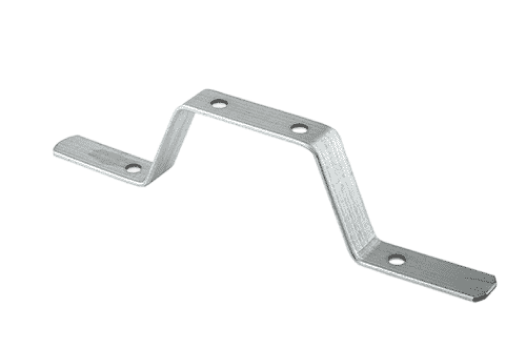

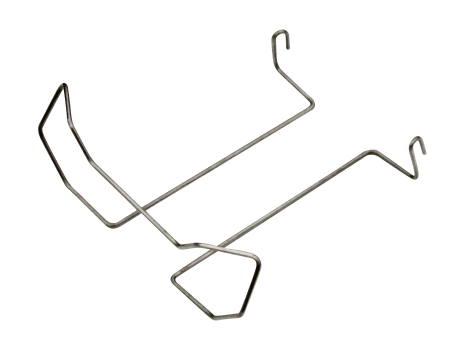

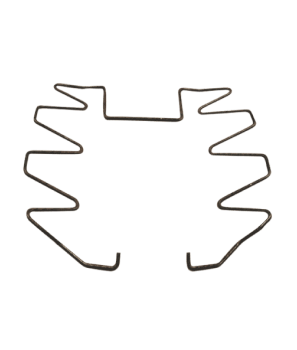

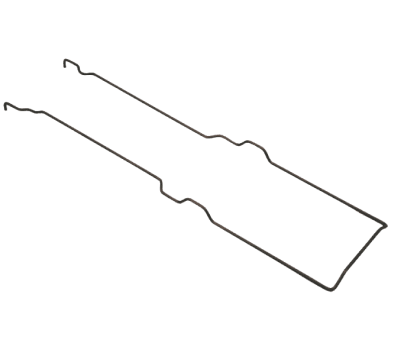

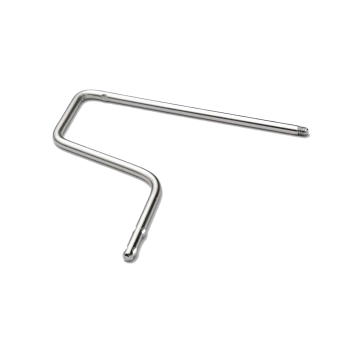

Parts that speak for themselves

Why choose our CNC wire bending machines?

Unmatched precision

Our CNC wire bending machines ensure precise bending, even for complex geometries.

Maximum flexibility

Adaptable to various diameters and configurations, our machines meet every need.

Low energy consumption

Our all-electric wire bending machines reduce energy consumption while delivering high performance.

Proven reliability

Over 30 years of durability, ensuring continuous production and minimal maintenance.

Innovative technology

Pioneers in electric technology, our machines integrate cutting-edge patented innovations.

Optimized productivity

Reduce cycle times while maintaining consistent quality for better efficiency.

Numalliance Wire Bending Machines in the Era of Industry 5.0

At Numalliance, we bring your workshop into Industry 5.0; an era where collaboration between people and technology achieves unprecedented precision, efficiency, and sustainability. Our full range, from the agile small wire bending machine to the high-performance 3d cnc wire bending machine, ensures every manufacturer benefits from flexibility and digital intelligence.

Each cnc wire bender is engineered to process wire or flat stock with perfect accuracy and adaptability. By integrating smart technologies, our equipment delivers an ideal balance of precision, repeatability, and customization. Operators can easily manage complex geometries, tight radii, and multi-reference production thanks to intuitive programming and user-friendly interfaces.

Beyond bending, Numalliance integrates secondary operations such as chamfering, welding, in-line control or punching directly into the workflow. The goal is to simplify the operator’s work while maintaining total control of the wire bending process.

Industry 5.0 is not just automation — it’s about placing the human operator at the heart of intelligent systems capable of predicting maintenance, monitoring quality in real time, and optimizing production rate. This synergy between humans and machines enables smoother workflows, less downtime, and reduced waste.

Across industries, our clients already see measurable results: higher productivity, better bending quality, and lower costs. With Industry 5.0, Numalliance ensures that every cnc wire bender remains connected, efficient, and future-ready; supporting smarter, more sustainable manufacturing.

Enter the world of Numalliance and discover how our bending machines redefine precision, performance, and flexibility. From the versatility of a small wire bending machine for short series to the advanced capabilities of a 3d cnc wire bending machine for complex geometries, our equipment meets the highest standards of wire and flat stock forming. Each machine delivers consistent quality, helping manufacturers to boost productivity while maintaining precision across every project.

Expertise Dedicated to Your Production

With more than 150 years of experience in wire and flat stock bending, Numalliance has become a global leader in designing and manufacturing full-electric CNC machines . Our know-how and patented technologies allow us to create tailor-made solutions suited to every industry and production scale.

Also, each model combines flexibility, accuracy, and long-term reliability. Our advanced bending machines range helps manufacturers minimize tooling costs, reduce changeover times, and ensure consistent quality at every stage.

Renowned for reliability and innovation, we continuously invest in R&D to enhance software, controls, tooling and components fully aligned with the standards of the industry of the future. Numalliance supports its customers from machine selection through commissioning, enabling metal wire bending to be integrated quickly and efficiently into production.

Choosing Numalliance means trusting recognized expertise in wire bending — with industrial solutions that not only address today’s manufacturing challenges but also anticipate the future of intelligent production.

Wire & Tube 2026

Numalliance, will be exhibiting at Wire & Tube 2026 — the renowned international trade fair dedicated to sheet metal processing and metalworking technologies.

Global Industrie 2026

Numalliance, a global expert in the design of cold forming machines for wire, tube, and flat material, will be exhibiting at Global Industrie 2026, the must-attend event showcasing industrial innovation and expertise.

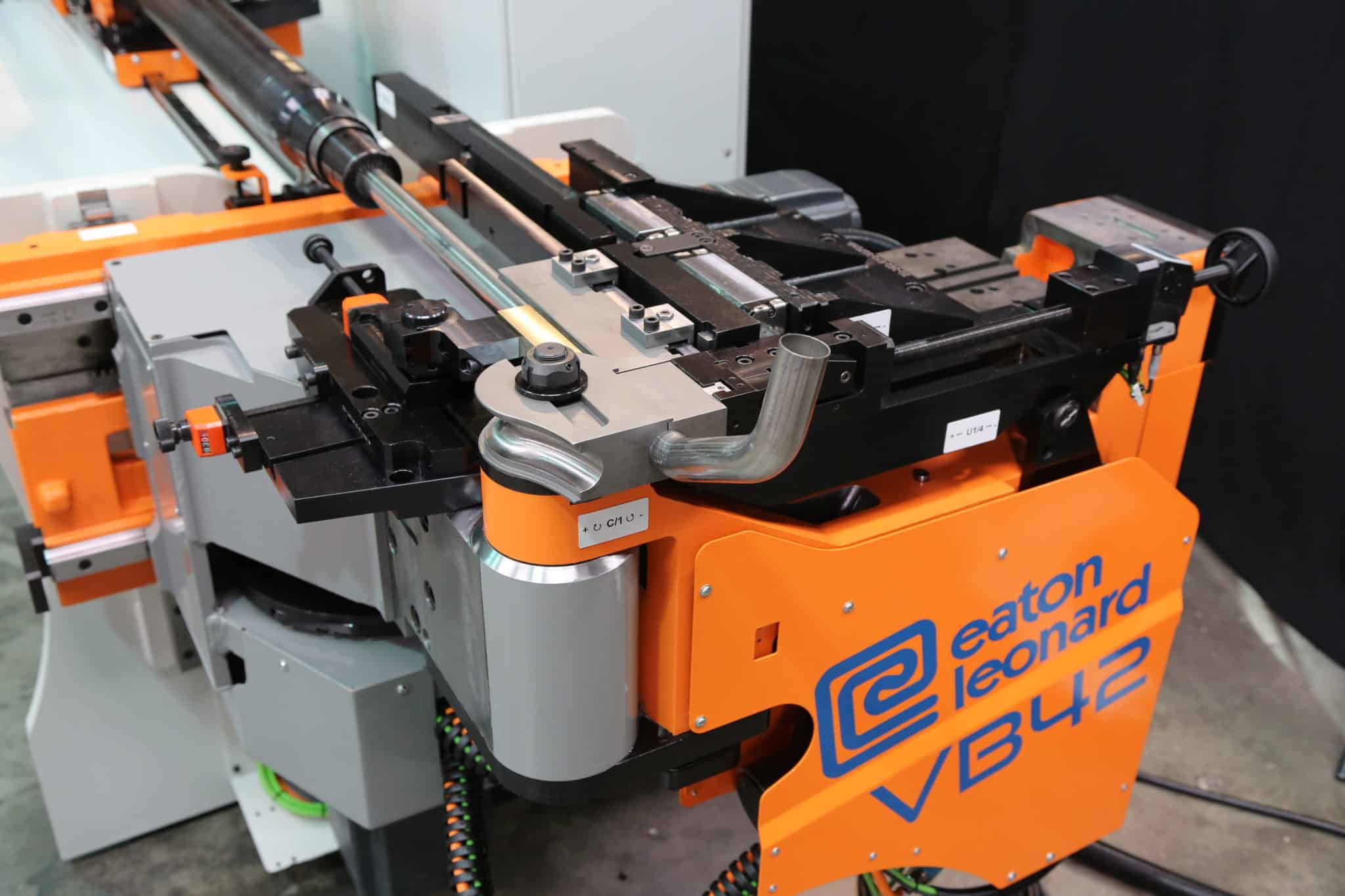

Eaton Leonard, the story of a brand that transformed the bending industry

Eaton Leonard, a brand of the Numalliance Group, has today become an internationally renowned name in tube bending and 3D measurement control.

Our experts are here to assist you. Whether you want to learn more or discuss a tailored solution, feel free to contact us.