Industry 4.0,

the Digital Solution to Produce Better, Faster

and more Accurately

A complete set of solutions tailored to your production needs

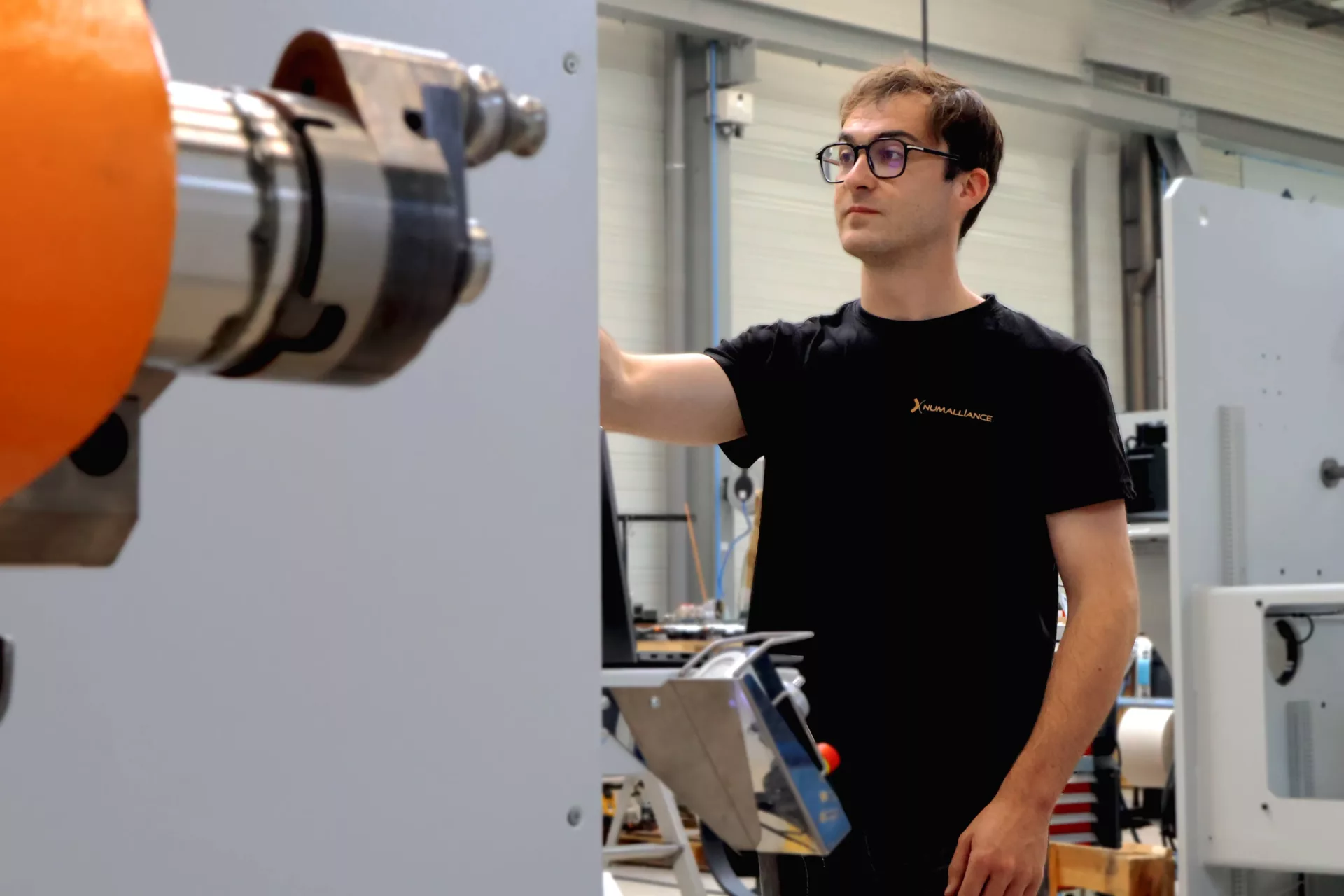

Numalliance’s R&D team is made up of expert engineers from a variety of different fields, all striving to develop ever more performing tools to help you get more efficient at producing your parts every day.

These tools and applications are bound together with the machine, to deliver adequate information and improve machine efficiency.

Multiple softwares to deliver higher performance

User-Friendly HMI to help run and set up the machine.

Track your production data remotely in real-time.

A must : 3D programming and production simulation of all types of parts prior to production.

Complementary softwares

Industry 4.0 at the core of your productivity

Production Tracking

your production data in real-time at your fingertips

User-Friendly HMI

Seamlessly define your part and its associated tooling, simulate and validate before your production run, thanks to our intuitive interface

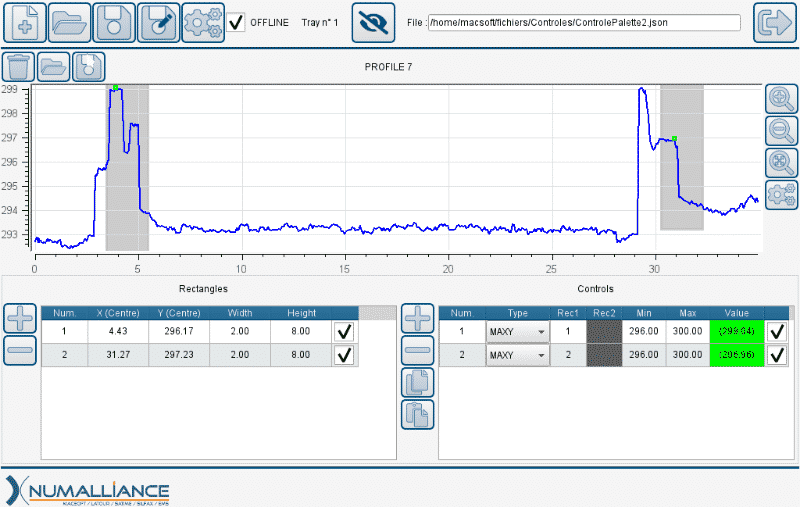

Gain control on final products

with intermediate control systems embedded in the workcell

Reduce scrap rate

and improve production with optimized programing tools

Enhanced UX with user friendly UI

that reduce part set up time and speed up change over

Documentation Industry 4.0

Looking for a reliable solution ?

In order to better meet your needs, please specify your sector of activity, the type of raw material (wire / tube / flat-stock) and any other information that can help us in your search for the most appropriate solution.

Looking to join us ? To apply for current openings or sending spontaneous applications, please visit our website : https://jobs.numalliance.com