Electric CNC Tube Bending Machines

The ideal solution for precise and high-performance tube bending, whatever your needs.

Our CNC Tube Bending Solutions

At Numalliance, we design and build machines that strike the perfect balance between precision and flexibility. As experienced cnc tube bending machine manufacturers for diameters up to 152mm with clockwise and/or counterclockwise bending. We design and deliver innovative and robust equipment that adapts to the requirements of the most demanding industrial sectors such as aeronautics, aerospace, automotive, HVAC, furniture, and more. Our wire benders ensure accurate bends, consistent quality, and higher productivity. Whether you need a reliable cnc pipe bending machine or a fully automated solution, our technology shapes performance into every detail.

TE small

From Ø.12 to Ø.78×.08″

(Ø3 to Ø20×2 mm)

Flexible, multi-height, and featuring quick tool change, ideal for bending small-diameter tubes.

Learn more

TE medium

From Ø.40 to Ø2×.08″

(Ø10 to Ø50×2 mm)

Robust, fast, and versatile, for bending intermediate-radius tubes in one or two directions.

Learn more

TE large

From Ø.80 to Ø4×.12″

(Ø20 to Ø102×3 mm)

Robust and rigid, capable of bending large-diameter multi-radius tubes in the clockwise direction.

Learn more

VB small

From Ø.12 to Ø.75″

(Ø3 to Ø19 mm)

Flexible, multi-height, and quick tool change

Eaton Leonard

Learn more

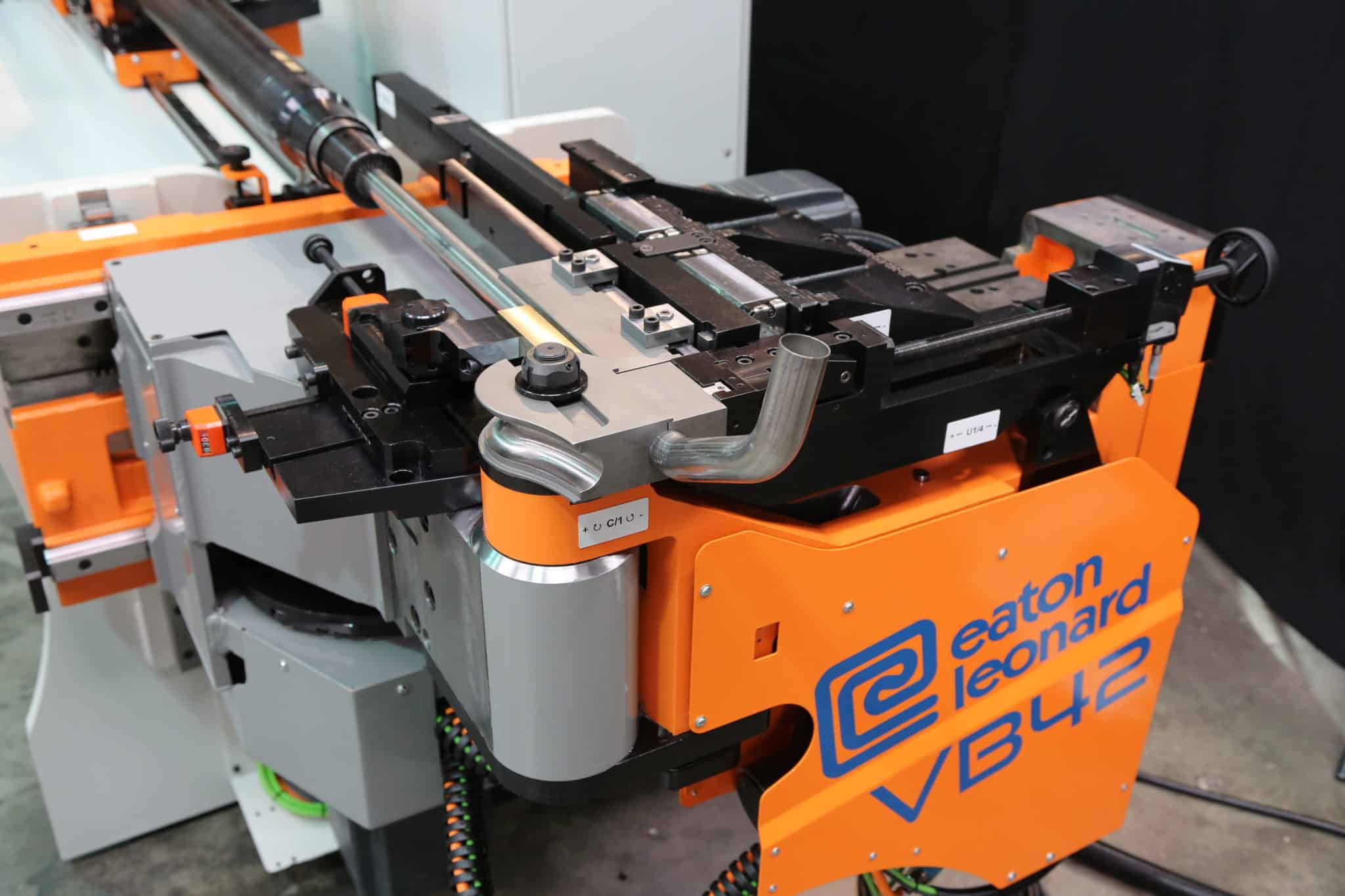

VB medium

From Ø.24 to Ø3″

(Ø6 to Ø76 mm)

Flexible, multi-height, and quick tool change

Eaton Leonard

Learn more

VB large

From Ø1 to Ø6″

(Ø25.4 to Ø152 mm)

Flexible, multi-height, and quick tool change

Eaton Leonard

Learn more

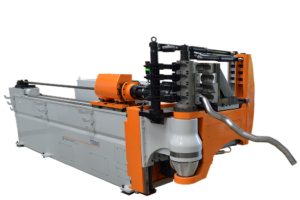

Numabend ST

From Ø.12 to Ø.375×.038″

(Ø3 to Ø10×1 mm)

Small-diameter tube bending, especially suited for brake lines, fuel lines, and HVAC systems.

Learn more

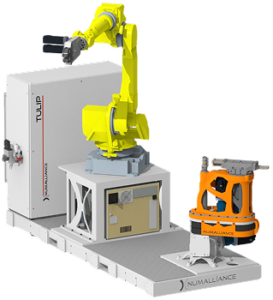

Tulip

From Ø.63 to Ø.75×.08″

(Ø15.8 to Ø19.05×2 mm)

Paired with an integrated robot, the Tulip 19 enables bending the most complex part shapes.

Learn more

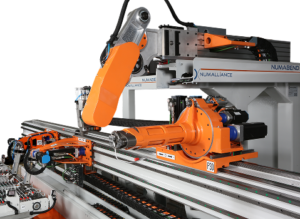

Numabend T815

From Ø.31×.04″ to Ø.59×.08″

(Ø8×1 to Ø15×2 mm)

Integrable into a cell for wire and tube forming from coils or pre-cut bars.

Learn more

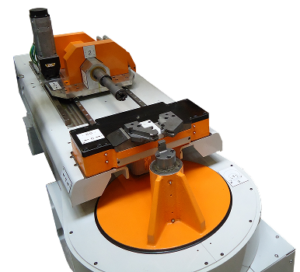

Numabend RT25

Up to Ø1×.12″

(Ø25.4×3 mm)

The ideal machine for long pre-cut tubes (up to 2m / 78.7″) with complex ends.

Learn more

Numatube 80

From Ø1 to Ø3.2×.08″

(Ø25 to Ø80×2 mm)

100% electric bending tube machine, ideal for

exhaust tubes

Learn more

High performance 3D Wire and Tube Bending Machines

Our unmatched expertise in wire bending technology gives us different perspectives to expand tube bending technologies in developing easy-to-use tools as well as feeding tube material directly as coil.

Parts produced on our bending tube machines

Find your CNC bending tube machine with the help of our experts.

Why choose our CNC bending tube machines?

Unmatched precision

Our CNC tube bending machines deliver highly precise bending in all directions, even for the most complex tube parts.

Maximum flexibility

Adaptable to various tube materials and diameters, our bending machines meet every production need.

Low energy consumption

Our all-electric bending tube machines reduce energy consumption while delivering high performance.

Proven reliability

With over 50 years of expertise, our tube bending solutions are proven, reliable, and designed to provide daily performance and accuracy.

Innovative technology

Always at the forefront, our CNC tube benders integrate patented innovations for unmatched bending results.

Optimized productivity

With reduced setup and quick changeover times, our tube bending machines significantly boost your productivity.

Numalliance CNC Tube Bending Machines and the Era of Industry 5.0

Our tube bending machines, designed with the latest technological developments, incorporate industrial connectivity and complete customization of your processes. The result: a range of tube bending machines designed to combine precision, flexibility, and efficiency.

Thanks to our digital solutions and the integration of secondary operations, transfers, and/or robots, our CNC tube bending machines can be easily adapted to the most specific specifications and needs of each customer. Industry 5.0 no longer just automates: it values humans as supervisors of an intelligent environment.

The constantly evolving software suite for our range of CNC tube bending machines simplifies programming, ensures reliable control, anticipates maintenance, provides real-time quality control, and manages multiple part references simultaneously for maximum flexibility and production optimization.

Our clients have already experienced increased productivity, enhanced part quality, and reduced waste. With Industry 5.0, Numalliance pushes further, enabling a smooth collaboration between human expertise and machine intelligence for smarter manufacturing and optimal performance.

Dive into the heart of Numalliance technology. See how our bending tube machines combine precision, flexibility, and innovation to meet the most demanding industry needs.

Expertise Dedicated to Your Production

With over 30 years of experience in cnc tube bending, Numalliance has become a worldwide leader among cnc full-electric and hydraulic tube bending machine manufacturers. Our patented technologies and expertise allow us to offer fully tailor-made solutions for any industry, ensuring that every client receives equipment suited to their specific production needs and their dedicated tools (bend die, mandrel, wiper die…

Renowned for reliability and continuous innovation, we help our clients optimize their operations with tube bending machines that combine robustness, high precision, and flexibility. By investing constantly in research and development, we stay ahead of technological change, guaranteeing long-lasting performance and greater efficiency for each cnc tube bending machine we build. Behind the scenes, a team of dedicated engineers is at work: one-third of our staff is dedicated to the engineering department, transforming each specific requirement into a concrete and effective industrial solution.

Choosing Numalliance means partnering with a company that blends expertise and innovation, delivering industrial solutions capable of meeting the challenges of today while preparing for tomorrow.

Wire & Tube 2026

Numalliance, will be exhibiting at Wire & Tube 2026 — the renowned international trade fair dedicated to sheet metal processing and metalworking technologies.

Global Industrie 2026

Numalliance, a global expert in the design of cold forming machines for wire, tube, and flat material, will be exhibiting at Global Industrie 2026, the must-attend event showcasing industrial innovation and expertise.

Eaton Leonard, the story of a brand that transformed the bending industry

Eaton Leonard, a brand of the Numalliance Group, has today become an internationally renowned name in tube bending and 3D measurement control.

Our experts are here to assist you. Whether you want to learn more or discuss a tailored solution, feel free to contact us.