From the first patent to comprehensive solutions: the Eaton Leonard journey

Eaton Leonard is above all the unique story of Leonard Zerlaut. Born in 1911 in Michigan, he grew up in an America that was in turmoil.

In 1929, during the Great Depression, his father, then a farmer, lost everything. The family then moved to California in search of a better future. Small jobs, the purchase of a hotel-restaurant, mounting debts… exhausted, his father eventually took his own life.

These hardships would leave a lasting mark on Leonard. He made it a principle never to go into debt and to pay cash for everything he purchased.

A meteoric start

Alongside his high school studies, Leonard took correspondence courses and quickly earned both his high school diploma and an electrical engineering degree. By the age of 22, he was already running a mechanical workshop, and later he bought the Chevrolet garage where he worked.

His ingenuity quickly became evident: he filed his first patent for a welding process that allowed tube bending, founded his workshop Leonard Precision Product, and became a supplier to Ford, the aviation industry, and the U.S. Navy during the war. His workshops then produced tools and equipment essential to the aerospace industry.

O.C History Roundup

Over the years, he accumulated no fewer than six patents, including:

- a flexible chuck (1955)

- a concrete shaping device (1959), notably used in the construction of Disneyland’s monorail.

- a feed system for a shrink-fitting machine (1966)

- a tube bending machine (1964)

Chairs, water heaters, metal structures—everything became a field for innovation. Leonard earned a rare reputation: tackling every challenge entrusted to him.

The company grew rapidly. In 1952, he moved to a larger site, soon comprising six buildings. The following year, he founded Tube Specialists of California, specializing in custom tubing. His clients came from all over the world, from Europe to Australia.

From Leonard Precision to Eaton Leonard

In 1967, he sold both companies, but one of his engineers, Homer Eaton, returned knocking at his door. Together, they conceived a revolutionary idea: developing a numerical control system for tube bending.

In 1973, Eaton Leonard was founded. Its first commercial product was the Vector 1 Tube Data Center. For the first time, a digital system connected to a tube bender allowed precise measurement and control of tube geometry, while electronically capturing data on the dimensions of bent tubes.

Patented by Eaton Leonard, this system revolutionized the bending industry by defining tubes as a series of intersecting vectors with automatic process correction, enabling the production of tube shapes with significantly greater accuracy.

A technical revolution? Not only that. The Vector 1 and its successors also eliminated many hours previously spent on dimension analysis and measurements, thereby significantly accelerating the production process.

More powerful than ever, the Vector 1—now called the VMS (Vector Measuring System)—has continued to evolve with the latest technological advances, incorporating new innovative features.

Today, the VMS can measure tubular parts before production to determine their exact dimensions even when they are unknown, providing significant time savings and enabling a faster production start.

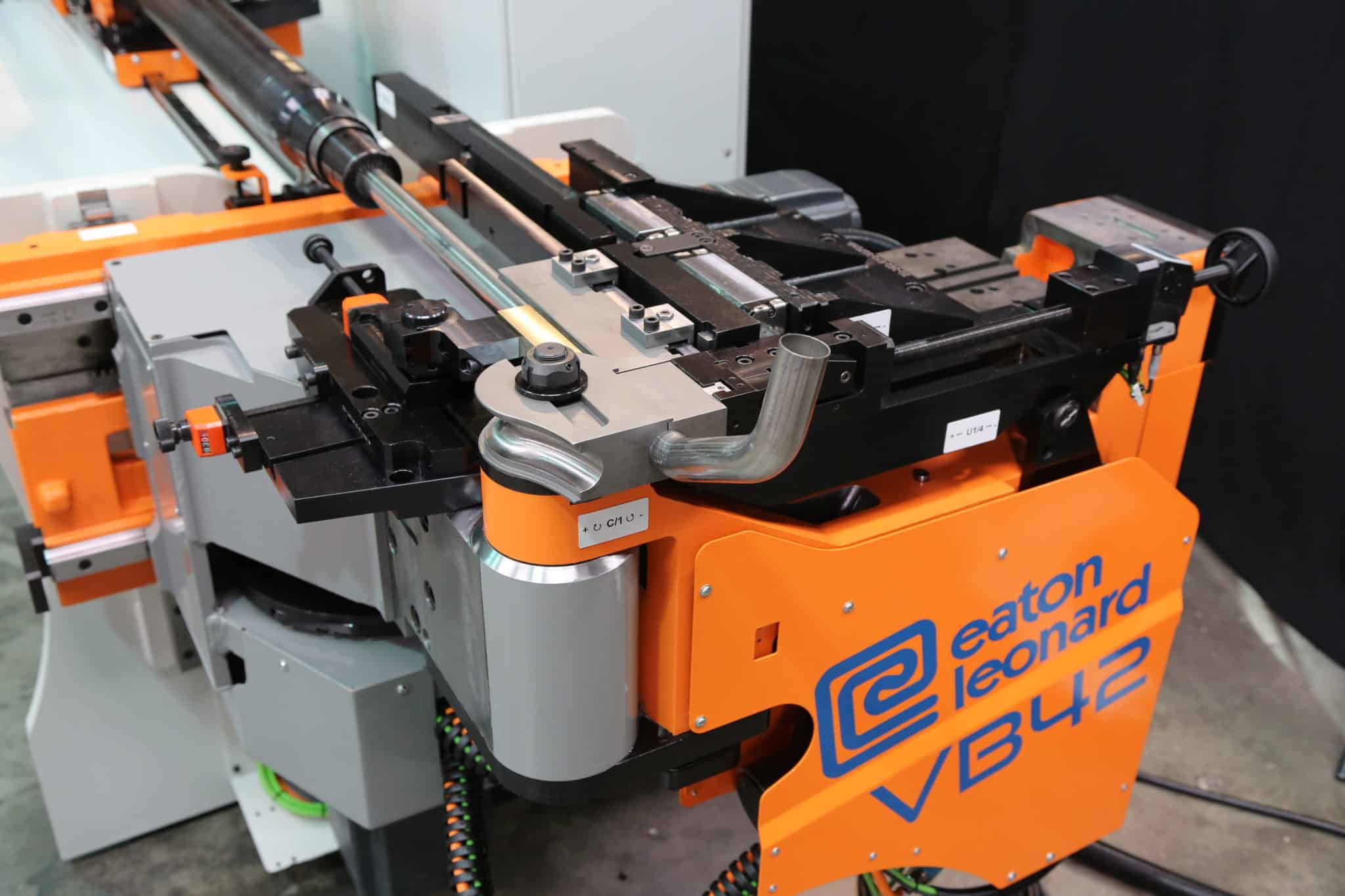

The following year, the Vectorbend 300GP, the first 3-axis digital tube bender, was launched. Programmable and reliable, it was exported by the hundreds worldwide, with some still in operation today. Linked to the Vector 1 Tube Data Center, it provided Eaton Leonard’s customers with a complete productivity solution.

In 1978, a new breakthrough emerged: the creation of Vector Pipeline, a method for rotating the bending tool around the tube, enabling successive bends while preventing the clamp from slipping, as often happened with conventional machines.

Innovations continued to follow one after another:

- The benders of the VB19, VB25, VB42, VB65, and VB90 series established themselves in the automotive, aerospace, HVAC, and commercial vehicle industries.

- The Tulip 19 is a fully electric tube bender equipped with an integrated robot. It automates tubeloading, bending, and unloading. Thanks to its robotic system, it can produce complex shapes while ensuring continuous, fast, and precise production.

- The VB80, supplied to a major aerospace player, is capable of bending stainless steel, titanium, and even Inconel for pipelines designed to withstand temperatures up to 400 °C.

Each innovation pushed the boundaries. Every machine bore the mark of Leonard’s ingenuity. Over the years, thanks to its numerous innovations, Eaton Leonard earned a reputation far beyond the American continent and quickly became a leader in the tube bending market. Leonard Zerlaut retired in the 1980s when the company was sold to an investment group.

If you want to learn more about the story of this genius, feel free to read the full article dedicated to him on Chris Jepsen’s website.

Merger and Global Expansion

In 2013, the company was acquired by AddisonMckee, a well-known bender manufacturer in the U.S. market, combining the ingenuity, creativity, and global reach of both companies and their employees to better serve customers worldwide, with subsidiaries in Canada, China, France, Mexico, and the United Kingdom.

In 2014, a new production facility was opened in Querétaro, Mexico, aimed at increasing the manufacturing capacity of benders and storing tools for the Mexican market.

In 2015, with the integration of Eagle Precision Technologies, a specialist in tube forming with nearly 8,000 benders installed worldwide, the company adopted the name Addition Manufacturing Technologies.

A new era for bending innovation

From America to Europe, from a small workshop to an international brand, Eaton Leonard has established itself as a leader in tube bending.

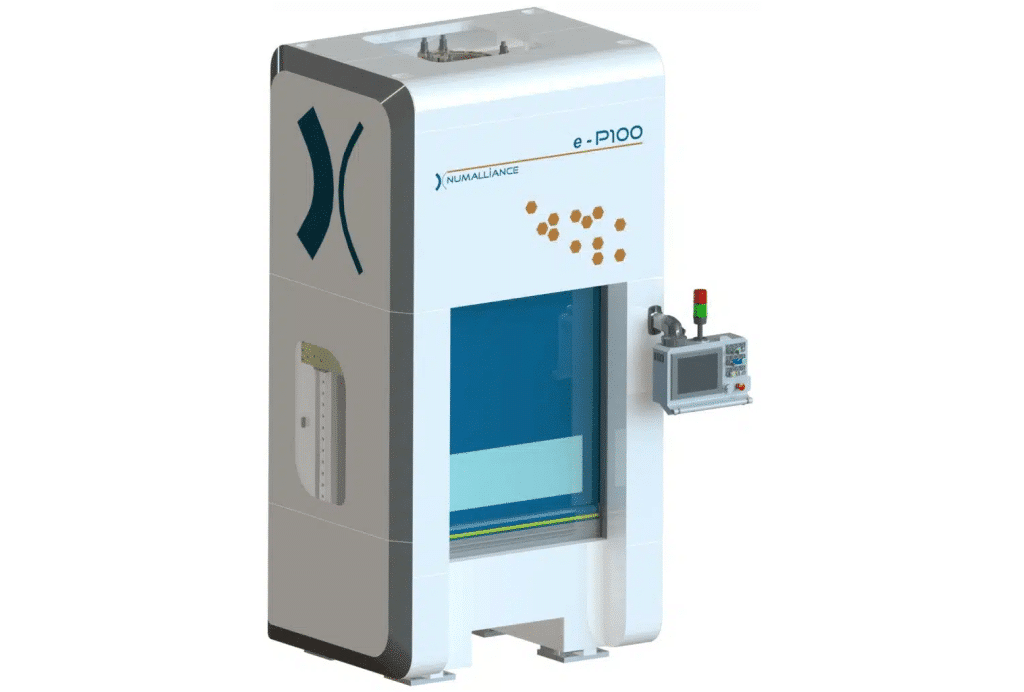

In 2020, a new chapter began: the assets of Addition Manufacturing Technologies were acquired by the Numalliance Group.

Numalliance’s growth through this merger reflects the group’s philosophy of integrating complementary brands and technologies to provide customers with complete solutions that meet all their needs. It also strengthens customer proximity through the development of a global network of sales and service technicians, supported by two new sites in the United States and Mexico dedicated to machine and tooling production. The merger has further consolidated the group’s R&D and engineering services, enabling work on numerous innovations for this year and the years ahead, keeping the company at the forefront of technology, particularly in Industry 4.0.

The story begun by Leonard Zerlaut, marked by resilience and innovation, continues to unfold today, and Eaton tube benders still have a bright future ahead.