CNC Tube End Forming Machines

Form your tubes with high precision and speed thanks to our industrial CNC machines

Discover our tube end forming machines

Our CNC tube end forming machines deliver high precision and optimal flexibility.

Designed to meet the demands of all industries, they allow flaring, reducing, swaging, and other secondary operations with fast cycle times and flawless repeatability.

Easy to integrate into your production lines, our solutions combine robustness, scalability, and productivity.

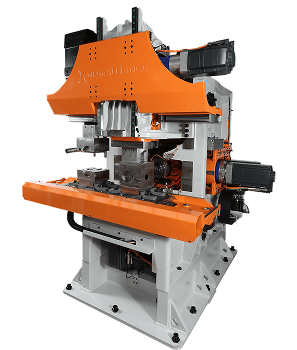

Numaform 8C

Working force: 8 t

Compact, ultra-fast, and versatile

Learn more

Numaform 5-8-12E

Working force: 5/8/12 t

Fast and fully electric, this compact end forming machine will surprise you with its performance.

Learn more

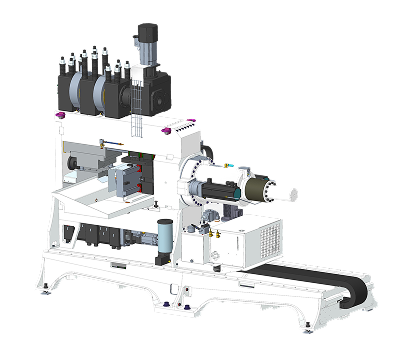

Numaform 30E

Working force: 30 t

High-performance electric end forming machine with hidden-time tool change and loading

Learn more

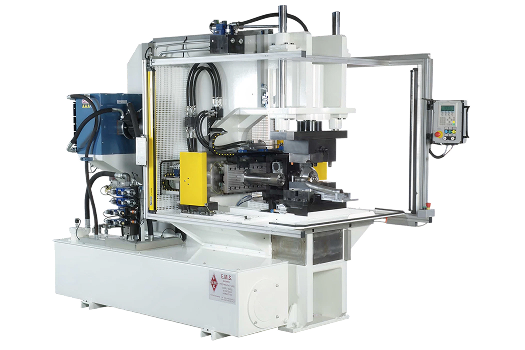

Numaform 70

Working force: 70 t

Electric end forming machine with 4-position tool changer

Learn more

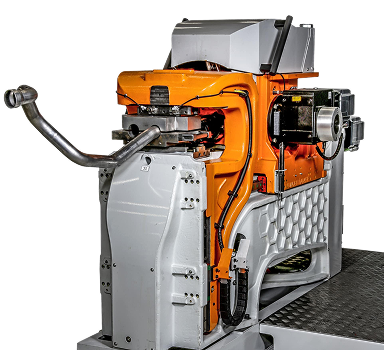

PHC

Working force: 3 to 16 t

A cost-effective and highly reliable solution for your forming needs

Learn more

40CC

Working force: 20 to 70 t

With its strength and reliability, the 40CC has become a trusted solution for your tube forming operations.

Learn more

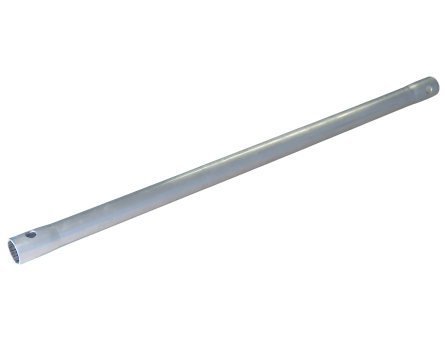

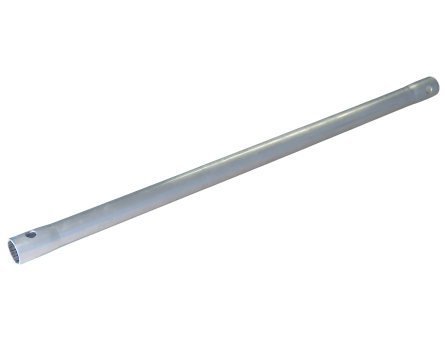

Parts that speak for themselves

Why choose our CNC end forming machines?

Unmatched precision

Our CNC end forming machines ensure precise forming, even for the most complex tube ends

Maximum flexibility

Adaptable to various diameters and configurations, our machines meet every need.

Low energy consumption

Our all-electric end forming machines reduce energy consumption while delivering high performance

Proven reliability

Over 30 years of durability, ensuring continuous production and minimal maintenance.

Innovative technology

Pioneers in electric technology, our machines integrate cutting-edge patented innovations.

Optimized productivity

Reduce cycle times while maintaining consistent quality for better efficiency.

Numalliance tube end forming machines and the era of Industry 5.0

At Numalliance, we bring your workshops into the era of Industry 5.0, where collaboration between humans and machines unlocks unmatched levels of performance.

Our tube end forming machines, designed to integrate smart technologies, combine precision, flexibility, and advanced customization, while being easily integrated into your production cells.

Thanks to our digital innovations and the integration of secondary operations such as chamfering, welding, or punching, our machines meet the specific needs of each client.

Industry 5.0 goes beyond automation: it puts the operator at the center of the process, with machines capable of anticipating maintenance, real-time quality control, and efficiently managing multi-part production.

Numalliance solutions already help many customers boost productivity, improve forming quality, and reduce waste.

With Industry 5.0, we go even further—creating a smooth and intelligent interaction between humans and machines, for tube production that is high-performing, sustainable, and connected.

See the performance, precision, and versatility of our CNC tube forming solutions

Expertise at the service of your production

With over 30 years of experience in tube forming, Numalliance is a leading player in the design of fully electric CNC end forming machines.

Our expertise, supported by proprietary and patented technologies, enables us to deliver tailor-made solutions, perfectly adapted to the requirements of each customer, whatever their industry.

Renowned for our reliability and our capacity to innovate, we support our clients in optimizing their production with robust, precise, and scalable end forming machines.

We continuously invest in R&D to remain at the forefront of technological advancements, offering durable, high-performance equipment that meets the standards of today’s and tomorrow’s industry.

Choosing Numalliance means trusting in proven expertise in tube end forming, with industrial solutions designed to meet today’s challenges—and anticipate those of tomorrow.

Wire & Tube 2026

Numalliance, will be exhibiting at Wire & Tube 2026 — the renowned international trade fair dedicated to sheet metal processing and metalworking technologies.

Global Industrie 2026

Numalliance, a global expert in the design of cold forming machines for wire, tube, and flat material, will be exhibiting at Global Industrie 2026, the must-attend event showcasing industrial innovation and expertise.

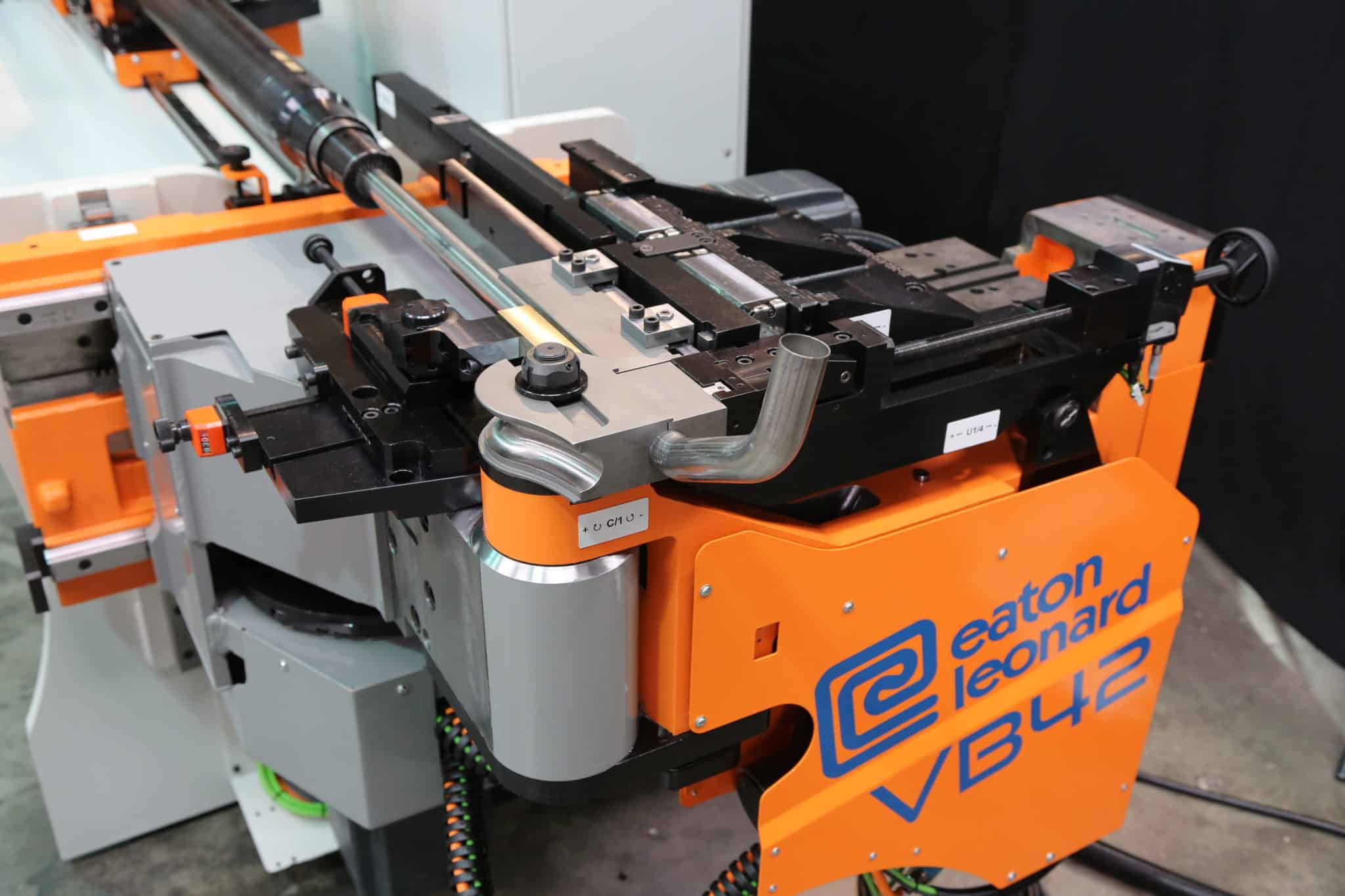

Eaton Leonard, the story of a brand that transformed the bending industry

Eaton Leonard, a brand of the Numalliance Group, has today become an internationally renowned name in tube bending and 3D measurement control.

Our experts are here to assist you. Whether you want to learn more or discuss a tailored solution, feel free to contact us.