Thanks to his Openness, Respect and Ingenious spirit, Justin Latour, who founded Latour et Fils in 1872 and developed wire, tube and strip bending machines, was able to best meet the requirements of his customers.

“Ingenuity”, because in the 1870s, while working as a mechanic in a factory in the Ennemane Valley (Ardennes region with strong industrial demand), Justin Latour created his own agricultural maintenance company that repaired transmission shafts , replaced the wooden cogs of mill gears as well as provided maintenance work for surrounding industries.

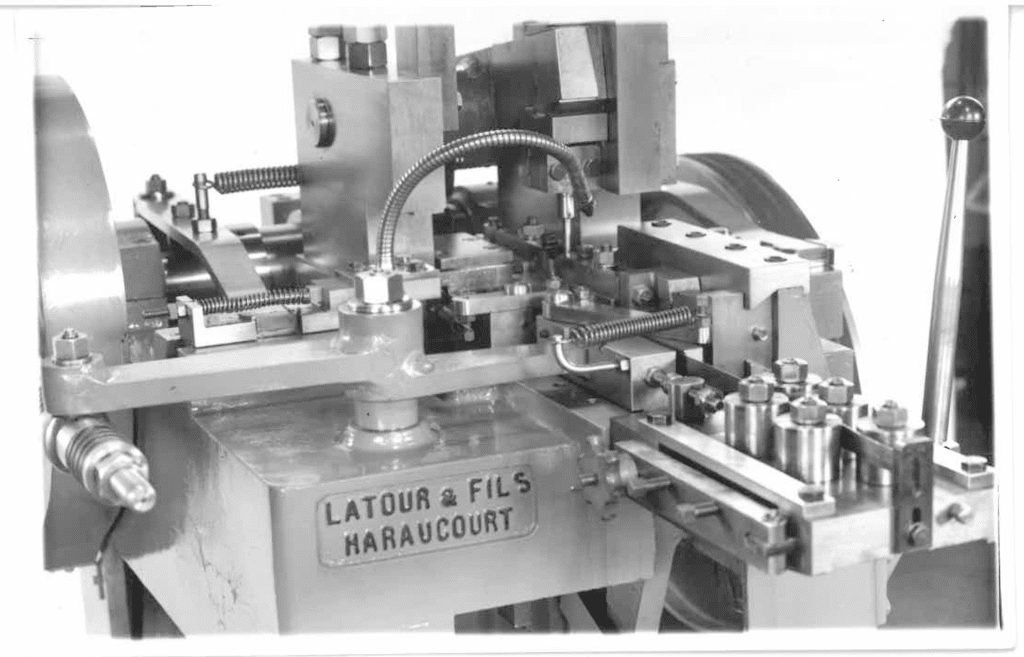

1910s onwards, the company “Latour & fils” produced not only woodworking machines, special machines or rotary wood lathes, but also a new range of machines with forced chains, Vaucanson (name of the famous French inventor and mechanic Jacques Vaucanson, born February 24, 1709 in Grenoble and died November 21, 1782 in Paris) bungee hook machines along with horizontal wire bending machines, which lead to what is currently known as sequential wire, tube and strip bending machines.

After the first “type 3” machine for production of slate hooks, other mechanical machines for manufacturing “jar collars” or machines for bottle caps expanded the range of solutions.

Gradually, these cam and mechanical slide machines allowed a production rate that met the growing needs of industry. The export of these machines gave new impetus to the company. After the first few exhibitions abroad in the 1970s, the company put in place a sales department particularly by the efforts of Mrs. and Mr. Jean Latour, grandson of the founder Justin Latour. In the 1960s, with the joining of Yves and Alain Latour, sons of Jean, the parents were able to devote time to acquire new markets abroad thus attaining 40% of sales from export: This concept illustrated to exemplify openness and willingness to invest.

The installation in 1965 in the premises of Haraucourt

…whoops ! not Haraucourt but Hachraucourt!

In this valley of Ennemane,there are two small villages that lie back to back: Raucourt and Haraucourt. The inhabitants who wish to go from one to the other, or to refer to their village of origin, the inhabitants of Haraucourt, for example, would refer to their village as Hachraucourt, , to avoid confusion.

A year before the death of Jean Latour, Yves Latour became majority CEO of the company in 1992 and further boosted the share of exports reaching 65% of sales, which facilitated the development of new technologies and in particular the birth of numerically controlled machines.

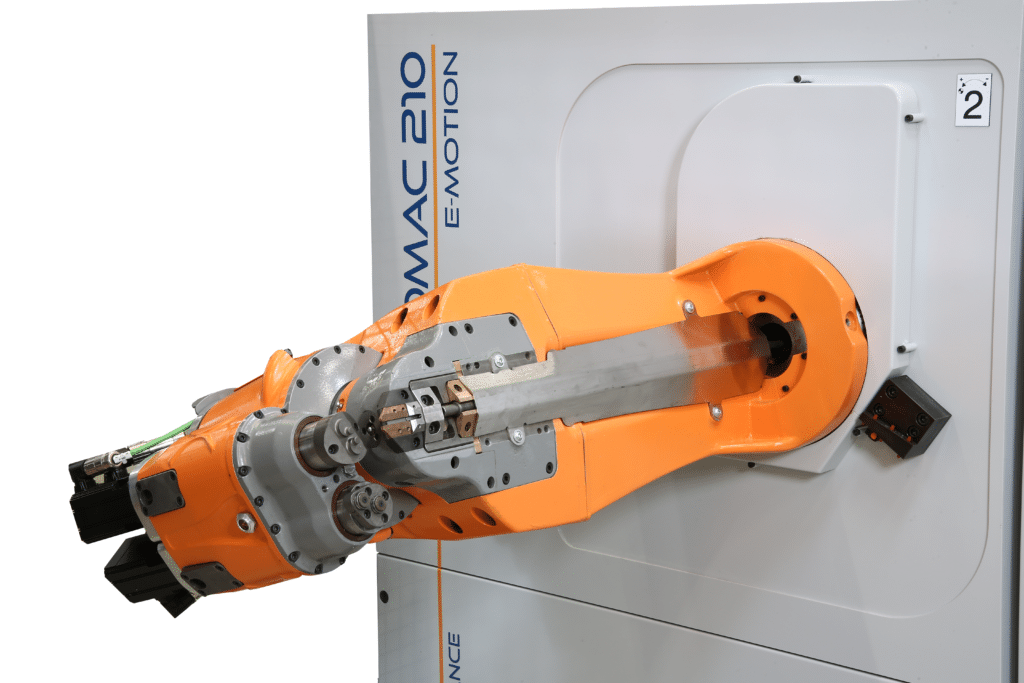

The Robomac

These wire bending machines (our flagship product on international wire market) were born in those years. With several numerically controlled axes their main feature, these machines bend wire from Ø 1 mm up to Ø 16 mm. Precursor of the robotized line, wire, tube and strip are bent sequentially following different steps:

- Straightening: Strating from coil, the wire is first straightened via a mechanism of straightening rollers.

- Feeding: The wire is fed into the machne done by a system of 4 motorized feed rollers, the feed speed may differs according to the part to be bent.

- Guiding: The wire then passes through an arm that rotates around the wire (can rotate clockwise and counterclockwise infinitely) thus avoiding any kind of twist or stress on the wire.

- Bending: Finally, the bending operation follows between two or three numerical axes, called bending heads and the “bending axes” which make it possible to obtain different radius.

- Cuting: The cutting tool cuts of the wire to complete the shape of the part.

- Depending on the feasibility study, Numalliance is able to offer you a Robomac model that can ensure precision, repeatability and production rate.

Representing the 5th generation of this family business, Yves Latour brilliantly embarked on the shift to numerical control while developing the company internationaly. For lack of space in the premises of Haraucourt, he built a new building in Bazeilles where the company moved in the early 2000s. Lacking a succesor within the family, Yves Latour sold his company in 2001 to his young French competitor MACSOFT, founded by Joël ETIENNE and Jean-François COUNILH. He continued to support the takeover of his business until his retirement.

Competitors but complementary, the 2 companies thus brought together offered to their customers a wide range of high-performance machines. The international presence also strengthened thanks to this acquisition: while LATOUR was present on an East-West axis (for example in the United States and Germany), MACSOFT was more present on a North-South axis (particularly in England and Italy).

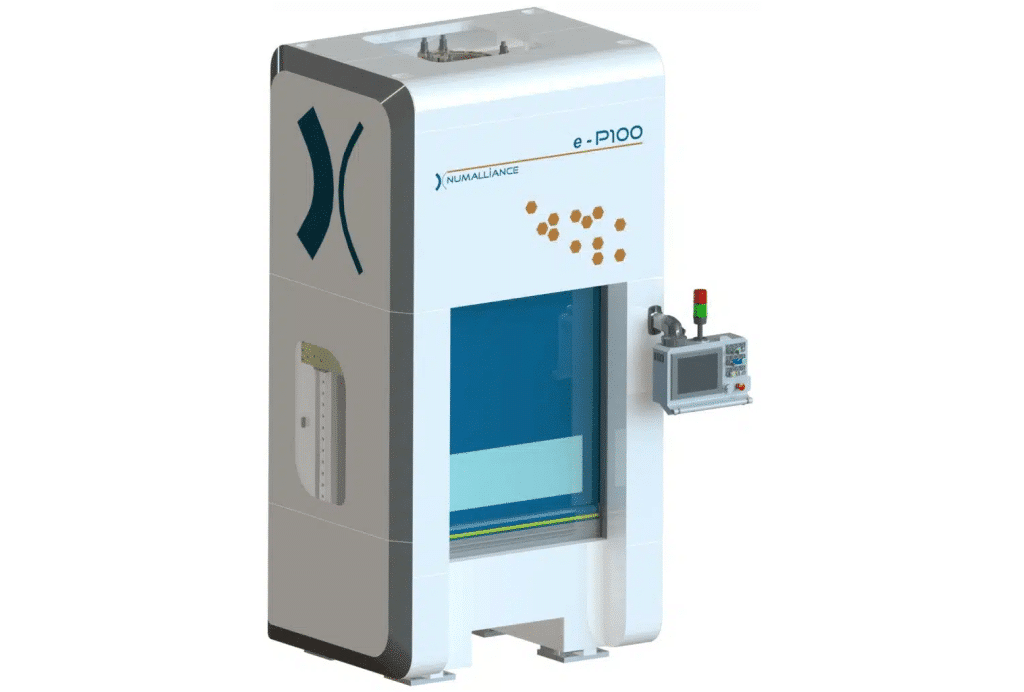

2 years after the takeover, MACSOFT, LATOUR and SATIME (a Breton company taken over in 2000, partner of Macsoft for machining and press tools) merged: the NUMALLIANCE group was thus born in 2003, and continues to develop products combining mechanics and numerical control technology. In 2005, the group developed its own numerical control: Touch & Form, and installed it on all its machines. This intuitive interface allows machine operators to quickly program the parts to be produced.

Today, the full range offered to customers can be from a simple 2D bending machine to a fully automated cell, including versatile bending machines such as the FTX. The range of Numalliance bending machines continues to expand depending on the requests from its customers. A wide range of secondary operations solutions also developed by Numalliance makes it possible to offer complete productivity solutions that best meet market needs.