| h-P100 | h-P200 | |

|---|---|---|

| Press specifications | Arch guiding ram | Arch guiding ram |

| Maximum force | 100T | 200T |

| Moving part | Upper platen | Upper platen |

| Tables/Platens dimensions | 800 x 600 mm | 1600 x 1200 mm |

| Tables / platens features | T-slots | T-slots |

| Number of main cylinders | (x1) | (x1) |

| Stroke | 500 mm | 1200 mm |

| Daylight | 800 mm | 1500 mm |

| Approach speed | 200 mm/s | 200 mm/s |

| Slow working speed | 15 mm/s | 10 mm/s |

| Fast opening speed | 150 mm/s | 150 mm/s |

| Operating control / Screen | Siemens S7 / 12" | Siemens S7 / 12" |

| Pressure sensor | analogic 0-10V | analogic 0-10V |

| Operator safety | Side panels + SICK light curtains in front | Side panels + SICK light curtains in front |

| Measuring rod stroke | Lineare analogic 0-10V | Lineare analogic 0-10V |

Parts made on h-P

Main features

- Low noise level

- Configurable cycle management

- Intuitive control panel

- Stroke and force control

- Controlled holding and decompression pressure

- Full tonnage throughout enitre stroke

- Conformity to hydraulic press and machine guidelines and norms

- Physical operator protection with safety valves

- Complete nomenclatures and technical specifications

Man / Machine interface

- Clean and silent operation

- High forming flexibility

- Long working life

- Controlled and accurate stroke

- Modular with optional functions

- Suitable for a wide range of applications

- Greater adaptability

- Integrated overload protection

- High tonnage capacity

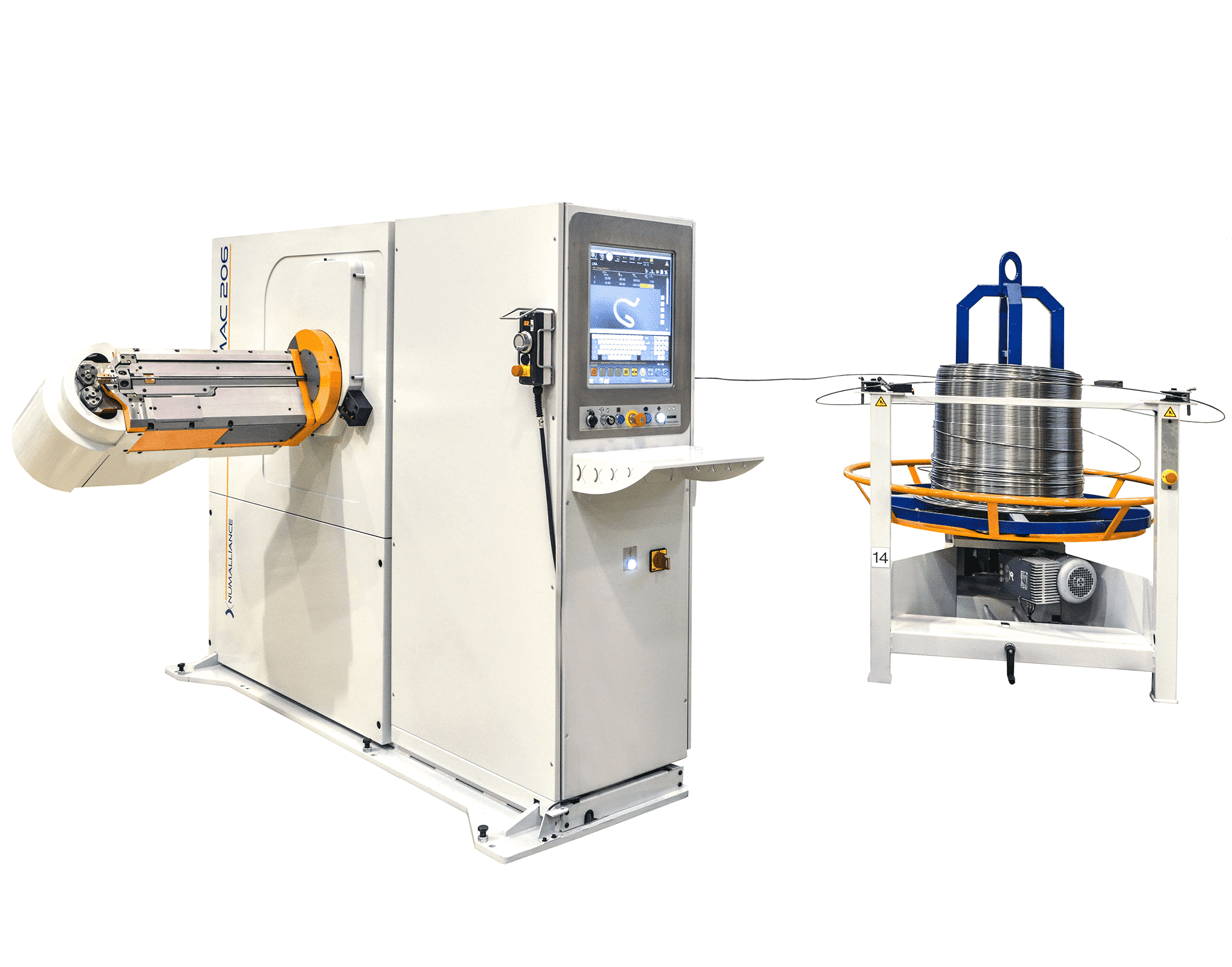

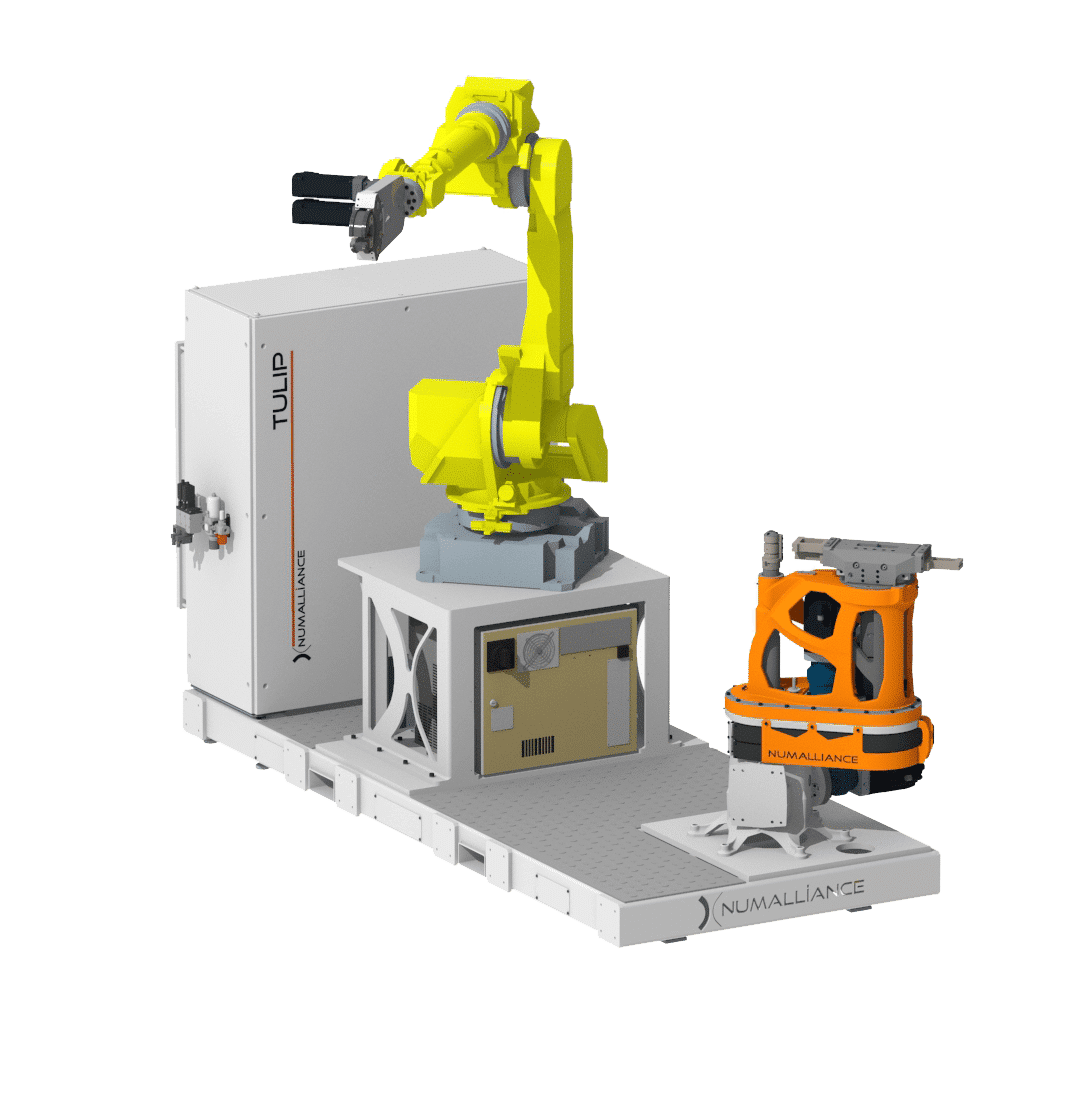

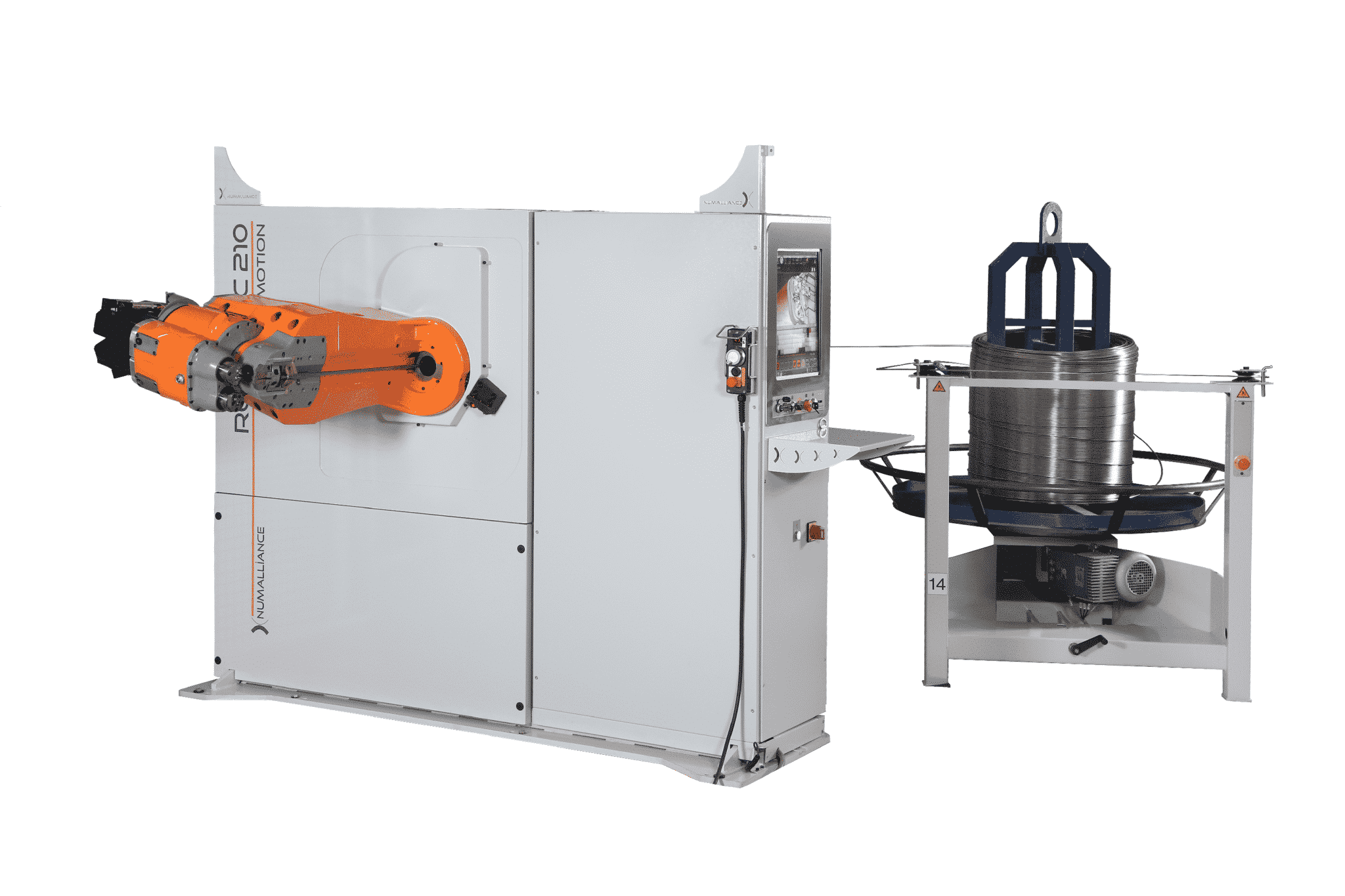

Leading manufacturer in productivity solutions for wire, tube and flatstock forming

With the expertise, history and experience of 9 brands gathered under one banner Numalliance is dedicated to satisfy your needs. From standard or custom built machines and workcells for tube, wire and flat stock bending, to special hydraulic presses, and all other secondary operations your end product might require.

Leading manufacturer in productivity solutions for wire, tube and flatstock bending, Numalliance conceives and realises standard or custom-made installations, integrating ancillary operations such as endforming, flattening, punching, assembly, welding, upsetting, chamfering, machining, threading… as well as inline dimensional control and self correction.

You are a producer of metal part in wire, tube or flatsotck parts, and look for a cost effective way of doing so. Numalliance will innovate with you and propose the optimized and high-performance solutions tailored to your specific objective

Numalliance is here to understand your needs and respond effectively